Sefani ya thovu ya Ceramic

Mafotokozedwe Akatundu

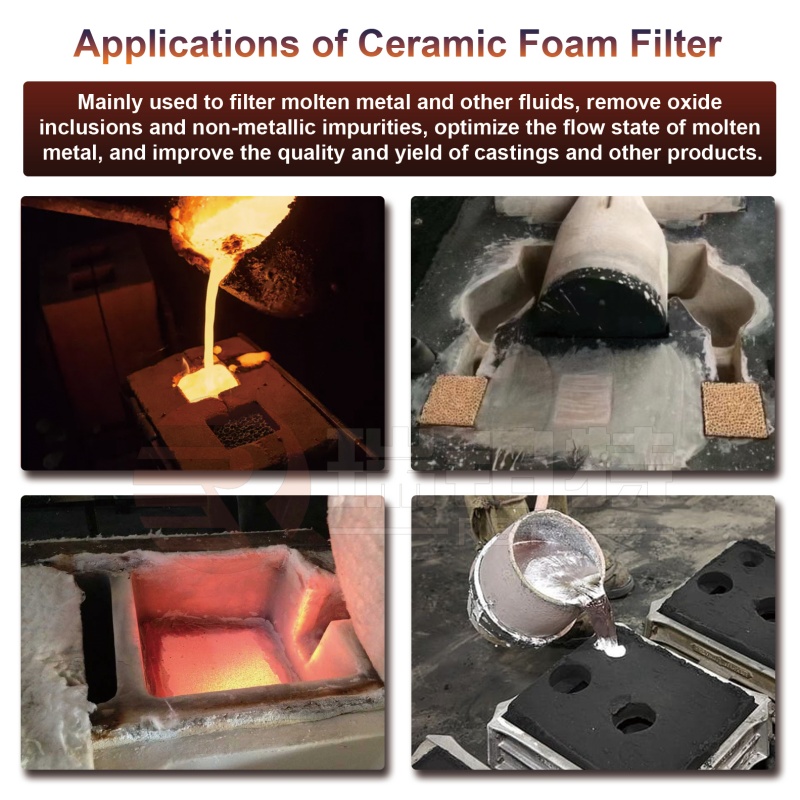

Fyuluta ya thovu la ceramicndi mtundu watsopano wa zinthu zomwe zimagwiritsidwa ntchito kusefa madzi monga chitsulo chosungunuka. Ili ndi kapangidwe kake kapadera komanso magwiridwe antchito abwino kwambiri ndipo imagwiritsidwa ntchito kwambiri m'mafakitale monga kuponyera zinthu.

1. Aluminiyamu:

Kutentha koyenera: 1250℃. Koyenera kusefa ndi kuyeretsa aluminiyamu ndi aloyi. Kumagwiritsidwa ntchito kwambiri popangira mchenga wamba komanso popangira nkhungu yokhazikika monga kupangira zida za aluminiyamu zamagalimoto.

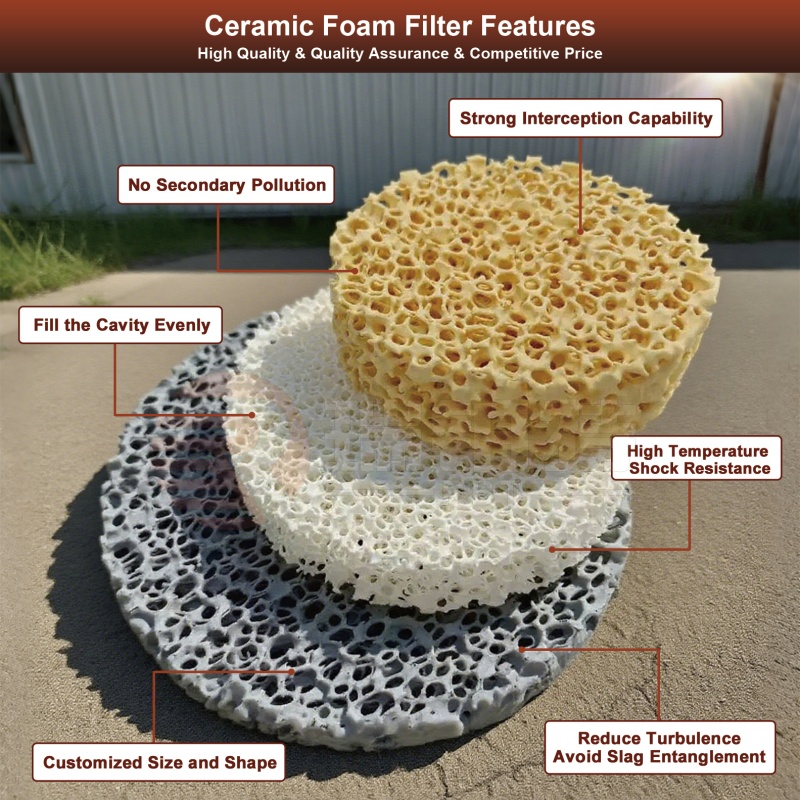

Ubwino:

(1) Chotsani zinyalala bwino.

(2) Kuyenda bwino kwa aluminiyamu yosungunuka bwino komanso yosavuta kudzaza.

(3) Chepetsani vuto la kuponyera, onjezerani ubwino wa pamwamba ndi katundu wa zinthu.

2. SIC

Ili ndi mphamvu komanso kukana kutentha kwambiri komanso dzimbiri la mankhwala, ndipo imatha kupirira kutentha kwambiri mpaka pafupifupi 1560°C. Ndi yoyenera kupangira zitsulo zamkuwa ndi chitsulo chosungunuka.

Ubwino:

(1) Chotsani zinyalala ndikuwonjezera kuyera kwa chitsulo chosungunuka bwino.

(2) Chepetsani kugwedezeka ndi kudzaza mofanana.

(3) Kuwongolera ubwino wa pamwamba pa kuponyera ndi kukolola, kuchepetsa chiopsezo cha chilema.

3. Zirconia

Kutentha kwake kosatentha ndi kokwera kuposa pafupifupi 1760℃, ndipo kumakhala ndi mphamvu zambiri komanso kukana kutentha kwambiri. Kumatha kuchotsa zinyalala bwino mu zitsulo zotayidwa ndi chitsulo ndikukweza ubwino wa pamwamba ndi mawonekedwe a makina a zitsulo zotayidwa.

Ubwino:

(1) Chepetsani zinyalala zazing'ono.

(2) Chepetsani vuto la pamwamba, onjezerani ubwino wa pamwamba.

(3) Chepetsani kupukutira, ndipo mtengo wake ndi wotsika.

4. Kugwirizana kochokera ku kaboni

Chopangidwa makamaka kuti chigwiritsidwe ntchito pa chitsulo cha kaboni ndi chitsulo chopanda aloyi ambiri, fyuluta ya thovu ya ceramic yochokera ku kaboni ndi yabwino kwambiri popangira zitsulo zazikulu. Imachotsa bwino zinyalala zazikulu kuchokera kuchitsulo chosungunuka pamene ikugwiritsa ntchito malo ake akuluakulu kuti itenge zinthu zazing'onoting'ono, kuonetsetsa kuti chitsulo chosungunukacho chadzazidwa bwino. Izi zimapangitsa kuti zitsulozo zikhale zoyera komanso zochepa.

chisokonezo.

Ubwino:

(1) Kuchuluka kochepa kwa zinthu, kulemera kochepa kwambiri komanso kutentha kwambiri, zomwe zimapangitsa kuti kutentha kukhale kochepa kwambiri. Izi zimalepheretsa chitsulo chosungunuka kuti chisaume mu fyuluta ndipo zimathandiza kuti chitsulocho chizidutsa mwachangu mu fyuluta. Kudzaza fyuluta nthawi yomweyo kumathandiza kuchepetsa kugwedezeka komwe kumachitika chifukwa cha zinthu zomwe zalowa m'malo mwake komanso matope.

(2) Njira zogwirira ntchito zomwe zimagwiritsidwa ntchito kwambiri, kuphatikizapo mchenga, chipolopolo, ndi kuponyera kolondola kwa ceramic.

(3) Kutentha kwakukulu kogwirira ntchito kwa 1650°C, zomwe zimapangitsa kuti njira zothira madzi zachikhalidwe zikhale zosavuta.

(4) Kapangidwe kapadera ka maukonde atatu kamayang'anira bwino kuyenda kwa chitsulo chosasunthika, zomwe zimapangitsa kuti kapangidwe kake kakhale kofanana mu chopoperacho.

(5) Amasefa bwino zinthu zing'onozing'ono zopanda chitsulo, zomwe zimathandiza kuti zinthu zina zigwire bwino ntchito.

(6) Zimawongolera mphamvu zonse za makina opangira, kuphatikizapo kuuma kwa pamwamba, mphamvu yokoka, kukana kutopa, ndi kutalika.

(7) Palibe vuto lililonse pa kusungunuka kwa zinthu zosefera zomwe zili ndi fyuluta.

Mndandanda wa Zamalonda

| Ma Model ndi Ma Parameter a Alumina Ceramic Foam Filters | |||||

| Chinthu | Mphamvu Yopanikizika (MPa) | Kuchuluka kwa madzi (%) | Kuchuluka kwa Zinthu (g/cm3) | Kutentha kwa Ntchito (≤℃) | Mapulogalamu |

| RBT-01 | ≥0.8 | 80-90 | 0.35-0.55 | 1200 | Aluminiyamu aloyi kuponyera |

| RBT-01B | ≥0.4 | 80-90 | 0.35-0.55 | 1200 | Kuponyera Aluminiyamu Yaikulu |

| Kukula ndi Kutha kwa Zosefera za Alumina Ceramic Foam | ||||

| Kukula (mm) | Kulemera (kg) | Kuchuluka kwa Mayendedwe (kg/s) | Kulemera (kg) | Kuchuluka kwa Mayendedwe (kg/s) |

| 10ppi | 20ppi | |||

| 50*50*22 | 42 | 2 | 30 | 1.5 |

| 75*75*22 | 96 | 5 | 67 | 4 |

| 100*100*22 | 170 | 9 | 120 | 7 |

| φ50*22 | 33 | 1.5 | 24 | 1.5 |

| φ75*22 | 75 | 4 | 53 | 3 |

| φ90*22 | 107 | 5 | 77 | 4.5 |

| Kukula Kwakukulu (Inchi) | Kulemera (Tani) 20,30,40ppi | Kuchuluka kwa Kuyenda (kg/mphindi) | ||

| 7"*7"*2" | 4.2 | 25-50 | ||

| 9"*9"*2" | 6 | 25-75 | ||

| 10"*10"*2" | 6.9 | 45-100 | ||

| 12"*12"*2" | 13.5 | 90-170 | ||

| 15"*15"*2" | 23.2 | 130-280 | ||

| 17"*17"*2" | 34.5 | 180-370 | ||

| 20"*20"*2" | 43.7 | 270-520 | ||

| 30"*23"*2" | 57.3 | 360-700 | ||

| Ma Model ndi Ma Parameter a SIC Ceramic Foam Filters | |||||

| Chinthu | Mphamvu Yopanikizika (MPa) | Kuchuluka kwa madzi (%) | Kuchuluka kwa Zinthu (g/cm3) | Kutentha kwa Ntchito (≤℃) | Mapulogalamu |

| RBT-0201 | ≥1.2 | ≥80 | 0.40-0.55 | 1480 | Chitsulo chosungunuka, chitsulo chotuwa ndi aloyi yopanda ferro |

| RBT-0202 | ≥1.5 | ≥80 | 0.35-0.60 | 1500 | Zopangira pouning mwachindunji ndi chitsulo chachikulu |

| RBT-0203 | ≥1.8 | ≥80 | 0.47-0.55 | 1480 | Za turbine ya mphepo ndi ma castings akuluakulu |

| Kukula ndi Kutha kwa Zosefera za SIC Ceramic Foam | ||||||||

| Kukula (mm) | 10ppi | 20ppi | ||||||

| Kulemera (kg) | Kuchuluka kwa Mayendedwe (kg/s) | Kulemera (kg) | Kuchuluka kwa Mayendedwe (kg/s) | |||||

| Imvi Chitsulo | Chitsulo Chopangidwa ndi Ductile | Chitsulo Chotuwa | Chitsulo Chopangidwa ndi Ductile | Chitsulo Chotuwa | Chitsulo Chopangidwa ndi Ductile | Chitsulo Chotuwa | Chitsulo Chopangidwa ndi Ductile | |

| 40*40*15 | 40 | 22 | 3.1 | 2.3 | 35 | 18 | 2.9 | 2.2 |

| 40*40*22 | 64 | 32 | 4 | 3 | 50 | 25 | 3.2 | 2.5 |

| 50*30*22 | 60 | 30 | 4 | 3 | 48 | 24 | 3.5 | 2.5 |

| 50*50*15 | 50 | 30 | 3.5 | 2.6 | 45 | 26 | 3.2 | 2.5 |

| 50*50*22 | 100 | 50 | 6 | 4 | 80 | 40 | 5 | 3 |

| 75*50*22 | 150 | 75 | 9 | 6 | 120 | 60 | 7 | 5 |

| 75*75*22 | 220 | 110 | 14 | 9 | 176 | 88 | 11 | 7 |

| 100*50*22 | 200 | 100 | 12 | 8 | 160 | 80 | 10 | 6.5 |

| 100*100*22 | 400 | 200 | 24 | 15 | 320 | 160 | 19 | 12 |

| 150*150*22 | 900 | 450 | 50 | 36 | 720 | 360 | 40 | 30 |

| 150*150*40 | 850-1000 | 650-850 | 52-65 | 54-70 | _ | _ | _ | _ |

| 300*150*40 | 1200-1500 | 1000-1300 | 75-95 | 77-100 | _ | _ | _ | _ |

| φ50*22 | 80 | 40 | 5 | 4 | 64 | 32 | 4 | 3.2 |

| φ60*22 | 110 | 55 | 6 | 5 | 88 | 44 | 4.8 | 4 |

| φ75*22 | 176 | 88 | 11 | 7 | 140 | 70 | 8.8 | 5.6 |

| φ80*22 | 200 | 100 | 12 | 8 | 160 | 80 | 9.6 | 6.4 |

| φ90*22 | 240 | 120 | 16 | 10 | 190 | 96 | 9.6 | 8 |

| φ100*22 | 314 | 157 | 19 | 12 | 252 | 126 | 15.2 | 9.6 |

| φ125*25 | 400 | 220 | 28 | 18 | 320 | 176 | 22.4 | 14.4 |

| Ma Model ndi Ma Parameter a Zirconia Ceramic Foam Filters | |||||

| Chinthu | Mphamvu Yopanikizika (MPa) | Kuchuluka kwa madzi (%) | Kuchuluka kwa Zinthu (g/cm3) | Kutentha kwa Ntchito (≤℃) | Mapulogalamu |

| RBT-03 | ≥2.0 | ≥80 | 0.75-1.00 | 1700 | Zachitsulo chosapanga dzimbiri, chitsulo cha kaboni ndi kusefera kwakukulu kwa chitsulo |

| Kukula ndi Kutha kwa Zirconia Ceramic Foam Filters | |||

| Kukula (mm) | Kuchuluka kwa Mayendedwe (kg/s) | Mphamvu (kg) | |

| Chitsulo cha Kaboni | Chitsulo Chopangidwa ndi Alloy | ||

| 50*50*22 | 2 | 3 | 55 |

| 50*50*25 | 2 | 3 | 55 |

| 55*55*25 | 4 | 5 | 75 |

| 60*60*22 | 3 | 4 | 80 |

| 60*60*25 | 4.5 | 5.5 | 86 |

| 66*66*22 | 3.5 | 5 | 97 |

| 75*75*25 | 4.5 | 7 | 120 |

| 100*100*25 | 8 | 10.5 | 220 |

| 125*125*30 | 18 | 20 | 375 |

| 150*150*30 | 18 | 23 | 490 |

| 200*200*35 | 48 | 53 | 960 |

| φ50*22 | 1.5 | 2.5 | 50 |

| φ50*25 | 1.5 | 2.5 | 50 |

| φ60*22 | 2 | 3.5 | 70 |

| φ60*25 | 2 | 3.5 | 70 |

| φ70*25 | 3 | 4.5 | 90 |

| φ75*25 | 3.5 | 5.5 | 110 |

| φ90*25 | 5 | 7.5 | 150 |

| φ100*25 | 6.5 | 9.5 | 180 |

| φ125*30 | 10 | 13 | 280 |

| φ150*30 | 13 | 17 | 400 |

| φ200*35 | 26 | 33 | 720 |

| Ma Model ndi Ma Parameter a Zosefera za Foam Zogwirizana ndi Carbon Ceramic Foam | |||||

| Chinthu | Mphamvu Yopanikizika (MPa) | Kuchuluka kwa madzi (%) | Kuchuluka kwa Zinthu (g/cm3) | Kutentha kwa Ntchito (≤℃) | Mapulogalamu |

| RBT-Kaboni | ≥1.0 | ≥76 | 0.4-0.55 | 1650 | Chitsulo cha kaboni, chitsulo chopanda aloyi, chitsulo chachikulu chopangidwa ndi chitsulo. |

| Kukula kwa Zosefera za Foam za Ceramic Foam zochokera ku Carbon | |

| 50*50*22 10/20ppi | φ50*22 10/20ppi |

| 55*55*25 10/20ppi | φ50*25 10/20ppi |

| 75*75*22 10/20ppi | φ60*25 10/20ppi |

| 75*75*25 10/20ppi | φ70*25 10/20ppi |

| 80*80*25 10/20ppi | φ75*25 10/20ppi |

| 90*90*25 10/20ppi | φ80*25 10/20ppi |

| 100*100*25 10/20ppi | φ90*25 10/20ppi |

| 125*125*30 10/20ppi | φ100*25 10/20ppi |

| 150*150*30 10/20ppi | φ125*30 10/20ppi |

| 175*175*30 10/20ppi | φ150*30 10/20ppi |

| 200*200*35 10/20ppi | φ200*35 10/20ppi |

| 250*250*35 10/20ppi | φ250*35 10/20ppi |

Mbiri Yakampani

Shandong Robert New Material Co., Ltd.ili ku Zibo City, Shandong Province, China, komwe ndi malo opangira zinthu zopinga. Ndife kampani yamakono yomwe imagwirizanitsa kafukufuku ndi chitukuko, kupanga, kugulitsa, kapangidwe ndi zomangamanga za uvuni, ukadaulo, ndi kutumiza zinthu zopinga. Tili ndi zida zonse, ukadaulo wapamwamba, mphamvu yaukadaulo yamphamvu, khalidwe labwino kwambiri la malonda, komanso mbiri yabwino. Fakitale yathu imakwirira maekala opitilira 200 ndipo kutulutsa kwapachaka kwa zinthu zopinga ndi pafupifupi matani 30000 ndipo zinthu zopinga ndi matani 12000.

Zinthu zathu zazikulu zopangidwa ndi zinthu zotsutsa ndi izi:zipangizo zotsukira za alkaline; zipangizo zotsukira za silikoni ya aluminiyamu; zipangizo zosaoneka ngati zotsukira; zipangizo zotenthetsera kutentha; zipangizo zapadera zotsukira; zipangizo zogwirira ntchito zotsukira za makina opitira patsogolo.

Mafunso Ofunsidwa Kawirikawiri

Mukufuna thandizo? Onetsetsani kuti mwapita ku malo athu othandizira kuti mupeze mayankho a mafunso anu!

Ndife opanga enieni, fakitale yathu yakhala ikupanga zinthu zotsutsa kwa zaka zoposa 30. Tikulonjeza kupereka mtengo wabwino kwambiri, ntchito yabwino kwambiri yogulitsa zinthu zisanagulitsidwe komanso zitagulitsidwa.

Pa njira iliyonse yopangira, RBT ili ndi dongosolo lathunthu la QC la kapangidwe ka mankhwala ndi mawonekedwe ake. Ndipo tidzayesa katunduyo, ndipo satifiketi yaubwino idzatumizidwa ndi katunduyo. Ngati muli ndi zofunikira zapadera, tidzayesetsa momwe tingathere kuti zigwirizane nazo.

Kutengera kuchuluka kwa katundu, nthawi yathu yotumizira ndi yosiyana. Koma tikulonjeza kutumiza mwachangu momwe tingathere ndi mtundu wotsimikizika.

Inde, timapereka zitsanzo zaulere.

Inde, ndithudi, mwalandiridwa kupita ku kampani ya RBT ndi zinthu zathu.

Palibe malire, titha kupereka malingaliro abwino kwambiri komanso yankho malinga ndi momwe zinthu zilili.

Takhala tikupanga zinthu zopinga kwa zaka zoposa 30, tili ndi chithandizo champhamvu chaukadaulo komanso chidziwitso chambiri, titha kuthandiza makasitomala kupanga ma uvuni osiyanasiyana ndikupereka chithandizo chimodzi chokha.