Wopanga Wotsogola wa SiSiC silicon carbide burner chubu cha uvuni chomwe chimayatsidwa kutentha kwambiri

Tsopano tili ndi zida zopangira zatsopano kwambiri, mainjiniya odziwa bwino ntchito komanso ogwira ntchito, makina owongolera apamwamba kwambiri komanso gulu la akatswiri odziwa bwino ntchito yopezera ndalama asanayambe/atagulitsa, othandizira opanga otsogola a SiSiC silicon carbide burner chubu cha uvuni chomwe chimayatsidwa kutentha kwambiri, Simungakhale ndi vuto lililonse lolankhulana nafe. Timalandira makasitomala padziko lonse lapansi kuti atithandize pa mgwirizano wa bungwe.

Tsopano tili ndi zida zopangira zatsopano kwambiri, mainjiniya odziwa bwino ntchito komanso ogwira ntchito oyenerera, makina owongolera apamwamba kwambiri komanso gulu la akatswiri othandiza anthu kupeza ndalama asanayambe/atagulitsa.Refractory ceramic ndi Reaction boned silicon carbide, Timapereka chithandizo chaukadaulo, kuyankha mwachangu, kutumiza nthawi yake, khalidwe labwino kwambiri komanso mtengo wabwino kwambiri kwa makasitomala athu. Kukhutira ndi mbiri yabwino kwa kasitomala aliyense ndiye chinthu chofunikira kwambiri kwa ife. Timayang'ana kwambiri chilichonse chokhudza kukonza maoda kwa makasitomala mpaka atalandira zinthu zotetezeka komanso zabwino komanso ntchito yabwino yoyendetsera zinthu komanso mtengo wotsika. Kutengera izi, katundu wathu amagulitsidwa bwino kwambiri m'maiko aku Africa, Middle-East ndi Southeast Asia. Potsatira malingaliro abizinesi akuti "kasitomala choyamba, pitilizani patsogolo", timalandira makasitomala ochokera kunyumba ndi kunja kuti agwirizane nafe.

Zambiri Zamalonda

1. Zogulitsa za SSiC (Zogulitsa za Silicon Carbide Zothira Madzi mu Atmospheric Sintering)

(1) Chida ichi ndi chopangidwa ndi SiC ceramic cholimba chomwe chimapangidwa ndi ufa wa SiC wopangidwa ndi mphamvu ya sub-micron yopanda mphamvu. Chilibe silicon yaulere ndipo chili ndi tinthu tating'onoting'ono.

(2) Pakadali pano ndi chinthu chomwe chimakonda kwambiri popanga mphete zomangira zamakina, ma nozzles ophulitsa mchenga, zida zoteteza zipolopolo, mapampu a maginito, ndi zida zopopera zam'chitini padziko lonse lapansi komanso zapakhomo.

(3) Ndi yoyenera makamaka kugwiritsidwa ntchito ponyamula zinthu zowononga monga ma asidi amphamvu ndi alkali amphamvu.

Mawonekedwe:

(1) Mphamvu kwambiri, kuuma kwambiri, kukana kutha, kukhuthala mpaka 3.1kg/m3.

(2) Kuchepa kwa mphamvu yamagetsi, kutentha kochepa, kukana kutentha kwambiri, kukana kutentha kwambiri.

(3) Kukhazikika kwa mankhwala, kukana dzimbiri, makamaka kukana hydrofluoric acid.

(4) Kukana kutentha kwambiri, kutentha kwakukulu kogwirira ntchito mpaka 1380 ℃.

(5) Nthawi yayitali yogwirira ntchito komanso kuchepetsa ndalama zonse zomwe zimagwiritsidwa ntchito poika ndalama.

2. Zogulitsa za RBSIC(SiSiC) (Zogulitsa za Silicon Carbide Zogwira Ntchito)

Silikoni yopangidwa ndi silicon ndi njira ya silicon yomwe imasakanikirana bwino ndikulowetsedwa ndi tinthu tating'onoting'ono ta SiC, ufa wa kaboni ndi zowonjezera molingana ndi kupanga SiC ndikusakanikirana ndi SiC, silicon yochulukirapo imadzaza mipata kuti ipeze zinthu zokhuthala kwambiri za ceramic.

Mawonekedwe:

Zipangizo za siliconized silicon carbide zili ndi zinthu monga mphamvu yayikulu, kuuma kwambiri, kukana kuvala, kulekerera kutentha kwambiri, kukana dzimbiri, kukana okosijeni kukana kutentha kwambiri, kukana kutentha kwambiri, kukana kutentha kwambiri, kukana kutentha kwambiri, kukana kutentha pang'ono, kukana kutentha pang'ono, kukana kutentha pang'ono, kukana kutentha kwambiri, kukana kutentha kwambiri, kukana kutentha kwambiri, kukana kutentha kwambiri, ndi zina zotero.

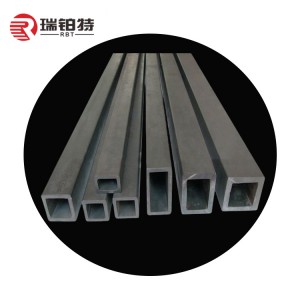

Zinthu zambiri zimatha kupangidwa kuchokera mmenemo monga matabwa, ma rollers, mapaipi oziziritsira mpweya, machubu oteteza kutentha, machubu oyezera kutentha, zida zotsekera, ndi zida zapadera zooneka ngati matabwa.

3. Zogulitsa za RSiC (Zogulitsa za Silicon Carbide Zobwezeretsedwanso)

Zogulitsa za RSiC zimatanthauza zinthu zosasunthika zopangidwa ndi silicon carbide ndi silicon carbide zomwe zimaphatikizidwa mwachindunji ndi silicon carbide. Zimadziwika ndi kusakhalapo kwa gawo lachiwiri. Zimapangidwa ndi 100% α-SiC ndipo ndi zipangizo zatsopano zosungira mphamvu mu uvuni zomwe zidapangidwa m'ma 1980.

Mawonekedwe:

Zinthu za RSiC zimagwiritsidwa ntchito makamaka ngati mipando ya uvuni, zomwe zili ndi ubwino wosunga mphamvu, kuwonjezera kuchuluka kwa uvuni, kufupikitsa nthawi yoyatsira moto, kukonza bwino ntchito yopangira uvuni, komanso phindu lalikulu pazachuma. Zingagwiritsidwenso ntchito ngati mitu ya nozzle ya burner, machubu otenthetsera a ceramic radiation, machubu oteteza zigawo (makamaka ma thermostat furnaces), ndi zina zotero.

4. Zogulitsa za SiC (Zogulitsa za Oxide Bonded Silicon Carbide)

Zinthu zosungunuka zosakanikirana ndi silicon carbide ngati gawo lalikulu la kristalo ndi oxide ngati gawo logwirizanitsa (zopangidwa ndi silicon dioxide bonded silicon carbide, zopangidwa ndi silicon carbide bonded mullite, ndi zina zotero). Zimagwiritsidwa ntchito kwambiri mu zitsulo, zoumba, zipangizo zomangira ndi mafakitale ena.

5. Zogulitsa za NSiC (Zogulitsa za Silicon Nitride Bonded Silicon Carbide)

Silicon nitride yophatikizidwa ndi silicon carbide ndi chinthu chatsopano, ndipo zinthu zake zazikulu ndi monga silicon nitride yophatikizidwa ndi machubu a silicon carbide owala, silicon nitride yophatikizidwa ndi njerwa za silicon carbide, silicon nitride yophatikizidwa ndi mbale za silicon carbide, ndi zina zotero. Imagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana monga chitsulo, zitsulo zopanda chitsulo, zipangizo zomangira mankhwala, ndi zina zotero, ndipo ili ndi zabwino zambiri monga kusunga mphamvu, kuteteza chilengedwe, kukana kutentha kwambiri, komanso kukana dzimbiri.

Zithunzi Zambiri

Kwa Makampani a Photovoltaics

Zogulitsa Zosagwira Ntchito

Zogulitsa Zosagwira Kutentha Kwambiri

Zogulitsa Zosagwira Ion Etching

Popeza pali mitundu yambiri ya zinthu za silicon carbide,

sitidzazilemba zonse pano.

Ngati mukufuna kusintha zinthu, chonde titumizireni uthenga.

Mndandanda wa Zamalonda

| Zogulitsa za RBSiC(SiSiC) | ||

| Chinthu | Chigawo | Deta |

| Kutentha Kwambiri kwa Ntchito | ℃ | ≤1380 |

| Kuchulukana | g/cm3 | >3.02 |

| Tsegulani Porosity | % | ≤0.1 |

| Mphamvu Yopindika | Mpa | 250(20℃); 280(1200℃) |

| Modulus of Elasticity | Gpa | 330(20℃); 300(1200℃) |

| Kutentha kwa Matenthedwe | W/mk | 45 (1200℃) |

| Kuchuluka kwa Kutentha | K-1*10-6 | 4.5 |

| Kuuma kwa Moh | 9.15 | |

| Asidi Yopanda Alkaline | Zabwino kwambiri | |

| Zogulitsa za SSiC | ||

| Chinthu | Chigawo | Zotsatira |

| Kuuma | HS | ≥115 |

| Chiŵerengero cha Kuyenda kwa Miyendo | % | <0.2 |

| Kuchulukana | g/cm3 | ≥3.10 |

| Mphamvu Yokakamiza | Mpa | ≥2500 |

| Mphamvu Yopindika | Mpa | ≥380 |

| Kuchuluka kwa Kukula | 10-6/℃ | 4.2 |

| Zomwe zili mu SiC | % | ≥98 |

| Si Yaulere | % | <1 |

| Modulus Yotanuka | Gpa | ≥410 |

| Kutentha | ℃ | 1400 |

Kugwiritsa ntchito

Zithunzi Zina

Mbiri Yakampani

Shandong Robert New Material Co., Ltd.ili ku Zibo City, Shandong Province, China, komwe ndi malo opangira zinthu zopinga. Ndife kampani yamakono yomwe imagwirizanitsa kafukufuku ndi chitukuko, kupanga, kugulitsa, kapangidwe ndi zomangamanga za uvuni, ukadaulo, ndi kutumiza zinthu zopinga. Tili ndi zida zonse, ukadaulo wapamwamba, mphamvu yaukadaulo yamphamvu, khalidwe labwino kwambiri la malonda, komanso mbiri yabwino. Fakitale yathu imakwirira maekala opitilira 200 ndipo kutulutsa kwapachaka kwa zinthu zopinga ndi pafupifupi matani 30000 ndipo zinthu zopinga ndi matani 12000.

Zinthu zathu zazikulu zomwe timapanga ndi monga: zinthu zotsutsana ndi alkaline; zinthu zotsutsana ndi silikoni ya aluminiyamu; zinthu zosaoneka ngati mawonekedwe a refractory; zinthu zotetezera kutentha; zipangizo zapadera zotsutsana ndi refractory; zipangizo zogwirira ntchito zotsutsana ndi refractory za makina oponyera mosalekeza.

Zinthu za Robert zimagwiritsidwa ntchito kwambiri m'ma uvuni otentha kwambiri monga zitsulo zopanda chitsulo, chitsulo, zipangizo zomangira ndi zomangamanga, mankhwala, mphamvu zamagetsi, kutentha zinyalala, ndi kukonza zinyalala zoopsa. Zimagwiritsidwanso ntchito m'makina achitsulo ndi chitsulo monga ma ladle, EAF, ma blast furnaces, ma converters, ma coke ovens, ma hot blast furnaces; ma burn ovens opanda chitsulo monga ma reverberators, ma reduction furnaces, ma blast furnaces, ndi ma rotary furnaces; zipangizo zomangira ma microwaves a mafakitale monga ma glass furnaces, simenti furnaces, ndi ma ceramic furnaces; ma microwave ena monga ma boilers, ma waste incinerators, roasting furnaces, omwe apeza zotsatira zabwino pakugwiritsa ntchito. Zinthu zathu zimatumizidwa ku Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas ndi mayiko ena, ndipo zakhazikitsa maziko abwino ogwirizana ndi mabizinesi ambiri odziwika bwino achitsulo. Ogwira ntchito onse a Robert akuyembekezera mwachidwi kugwira ntchito nanu kuti zinthu ziyende bwino.

Mafunso Ofunsidwa Kawirikawiri

Mukufuna thandizo? Onetsetsani kuti mwapita ku malo athu othandizira kuti mupeze mayankho a mafunso anu!

Kodi ndinu wopanga kapena wogulitsa?

Ndife opanga enieni, fakitale yathu yakhala ikupanga zinthu zotsutsa kwa zaka zoposa 30. Tikulonjeza kupereka mtengo wabwino kwambiri, ntchito yabwino kwambiri yogulitsa zinthu zisanagulitsidwe komanso zitagulitsidwa.

Kodi mumalamulira bwanji khalidwe lanu?

Pa njira iliyonse yopangira, RBT ili ndi dongosolo lathunthu la QC la kapangidwe ka mankhwala ndi mawonekedwe ake. Ndipo tidzayesa katunduyo, ndipo satifiketi yaubwino idzatumizidwa ndi katunduyo. Ngati muli ndi zofunikira zapadera, tidzayesetsa momwe tingathere kuti zigwirizane nazo.

Kodi nthawi yanu yobweretsera ndi iti?

Kutengera kuchuluka kwa katundu, nthawi yathu yotumizira ndi yosiyana. Koma tikulonjeza kutumiza mwachangu momwe tingathere ndi mtundu wotsimikizika.

Kodi mumapereka zitsanzo zaulere?

Inde, timapereka zitsanzo zaulere.

Kodi tingapite ku kampani yanu?

Inde, ndithudi, mwalandiridwa kupita ku kampani ya RBT ndi zinthu zathu.

Kodi MOQ yoyitanitsa mayeso ndi chiyani?

Palibe malire, titha kupereka malingaliro abwino kwambiri komanso yankho malinga ndi momwe zinthu zilili.

Chifukwa chiyani mutisankhe?

Takhala tikupanga zinthu zopinga kwa zaka zoposa 30, tili ndi chithandizo champhamvu chaukadaulo komanso chidziwitso chambiri, titha kuthandiza makasitomala kupanga ma uvuni osiyanasiyana ndikupereka chithandizo chimodzi chokha.

Tsopano tili ndi zida zopangira zatsopano kwambiri, mainjiniya odziwa bwino ntchito komanso ogwira ntchito, makina owongolera apamwamba kwambiri komanso gulu la akatswiri odziwa bwino ntchito yopezera ndalama asanayambe/atagulitsa, othandizira opanga otsogola a SiSiC silicon carbide burner chubu cha uvuni chomwe chimayatsidwa kutentha kwambiri, Simungakhale ndi vuto lililonse lolankhulana nafe. Timalandira makasitomala padziko lonse lapansi kuti atithandize pa mgwirizano wa bungwe.

Wopanga Wamkulu waRefractory ceramic ndi Reaction boned silicon carbide, Timapereka chithandizo chaukadaulo, kuyankha mwachangu, kutumiza nthawi yake, khalidwe labwino kwambiri komanso mtengo wabwino kwambiri kwa makasitomala athu. Kukhutira ndi mbiri yabwino kwa kasitomala aliyense ndiye chinthu chofunikira kwambiri kwa ife. Timayang'ana kwambiri chilichonse chokhudza kukonza maoda kwa makasitomala mpaka atalandira zinthu zotetezeka komanso zabwino komanso ntchito yabwino yoyendetsera zinthu komanso mtengo wotsika. Kutengera izi, katundu wathu amagulitsidwa bwino kwambiri m'maiko aku Africa, Middle-East ndi Southeast Asia. Potsatira malingaliro abizinesi akuti "kasitomala choyamba, pitilizani patsogolo", timalandira makasitomala ochokera kunyumba ndi kunja kuti agwirizane nafe.