Wopepuka Castable

Zambiri Zamalonda

| Dzina lazogulitsa | Refractory Castable |

| Magulu | Otsika simenti castable / Mphamvu yapamwamba castable / High aluminiyamu castable / Wopepuka castable |

| Kupanga | Refractory aggregates, ufa ndi binders |

| Mawonekedwe | 1. Kumanga kosavuta 2. Good slag kukana 3. Good dzimbiri kukana 4. Kukana moto wabwino 5. Kupulumutsa mphamvu ndi kuteteza chilengedwe |

| Zogulitsa | Low Cement Castable | High Mphamvu Castable |

| Kufotokozera | Zopangira simenti zochepa zimatanthawuza zoponyera zatsopano zomangira simenti zochepa kwambiri.Simenti zomwe zili muzitsulo zotayira nthawi zambiri zimakhala 15% mpaka 20%, ndipo simenti yomwe ili muzitsulo zochepa za simenti imakhala pafupifupi 5%, ndipo zina zimachepetsedwa kufika 1% mpaka 2%. | Mphamvu yapamwamba yosamva kuvala imapangidwa ndi mphamvu zambiri, mineral admixtures, aggregate yamphamvu kwambiri komanso anti crack and wear-resistant agent. |

| Mawonekedwe | Kukana kutenthedwa kwa kutentha, kukana kwa slag, ndi kukana kukokoloka kumakhala bwino kwambiri, kuposa njerwa zofananira zofanana. | Mphamvu zazikulu, kukana kuvala kwakukulu, kukana kukhudzidwa, kukana kukokoloka, kutsika kwamafuta, kuwongolera mawonekedwe mopanda pake, kukhulupirika kolimba, zomangamanga zosavuta, ntchito yomanga yabwino, komanso ntchito yayitali. |

| Mapulogalamu | 1. Kuyika kwa ng'anjo zosiyanasiyana zochizira kutentha, ng'anjo zotenthetsera, ng'anjo za shaft, ng'anjo zozungulira, zovundikira ng'anjo yamagetsi, ng'anjo zophulika; 2. Zodzikongoletsera zotsika-simenti ndizoyenera kupangira zida zamfuti zamafuta opopera ndi petrochemical catalytic cracking reactors Valani zosagwira akalowa, akalowa akunja a Kutentha ng'anjo madzi utakhazikika chitoliro, etc. | Mzere wosanjikiza wosamva kuvala wa slag sluice,mbiya, chopozera malasha, hopper ndi silo muzitsulo, malasha, mphamvu yamafuta, mankhwala,simenti ndi mafakitale ena, ndi kuphulika ng'anjo kusakaniza silo, sintering silo, wodyetsa, pelletizer, etc. |

| Zogulitsa | High Alumina Castable | Wopepuka Castable |

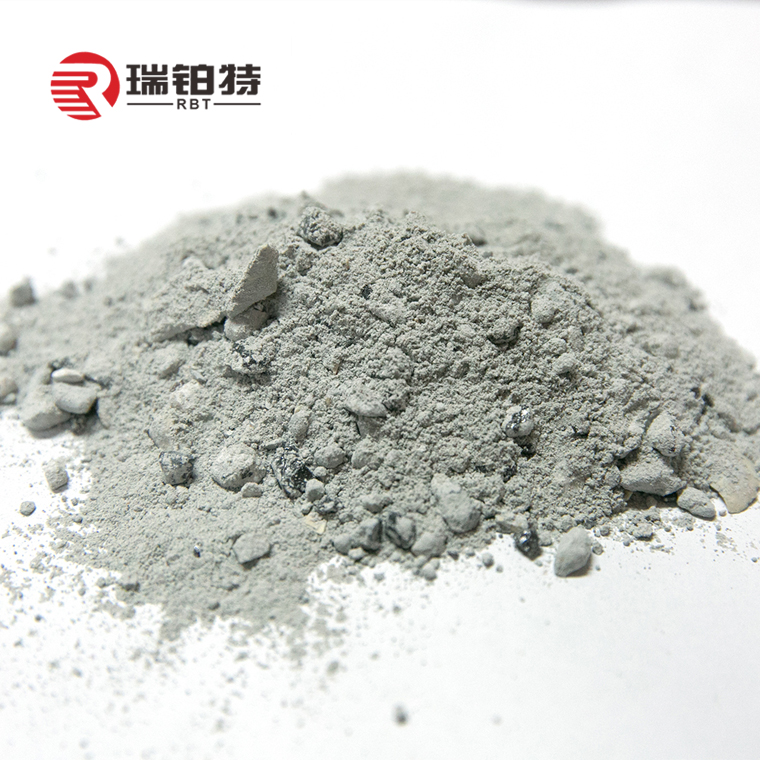

| Kufotokozera | Ma aluminiyamu apamwamba kwambiri amakanizidwama castables opangidwa ndi aluminiyamu yapamwamba kwambirimonga aggregates ndi ufa, ndi kuwonjezerandi zomangira. | Chonyezimira chopepuka chokhala ndi kachulukidwe kochepa kwambiri chimapangidwa ndi simenti ya aluminate, zinthu zabwino za aluminiyamu, ceramsite, ndi zowonjezera. |

| Mawonekedwe | Ali ndi mphamvu zamakina apamwamba komanso kukana kwamphamvu kwamafuta, kukana kwa abrasion ndi zinthu zina. | Kachulukidwe kachulukidwe kakang'ono, kachulukidwe kakang'ono ka matenthedwe, mphamvu yabwino yotchinjiriza, mphamvu yopondereza, asidi ndi kukana kwa gasi wa asidi, kutsekereza kutentha, kutchinjiriza kwamafuta, komanso kuyamwa kwamadzi otsika. |

| Mapulogalamu | Amagwiritsidwa ntchito makamaka ngati akalowa mkati mwa ma boilers, kuphulika kwa ng'anjo yoyaka moto, ng'anjo zowotchera, ng'anjo za ceramic ndi ma kilns ena. | The opepuka castable angagwiritsidwe ntchito kwa matenthedwe kutchinjiriza wosanjikiza wa mkulu-kutentha mafakitale ng'anjo ndi zida amagwiritsidwanso ntchito akalowa zosiyanasiyana mkulu-kutentha chitoliro gasi. |

Mndandanda wazinthu

| Dzina lazogulitsa | Wopepuka Castable | ||||||

| Kutentha Kwambiri Kugwira Ntchito | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Kuchulukana Kwambiri (g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus of Rupture (MPa) ≥ | 110 ℃ × 24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400 ℃ × 3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Cold Crushing Mphamvu (MPa) ≥ | 110 ℃ × 24h | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400 ℃ × 3h | ― | ― | 15 | 22 | 14 | ||

| Kusintha kwa Linear Kwamuyaya(%) | 1100 ℃ × 3h | -0.65 1000 ℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400 ℃ × 3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Thermal Conductivity (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Kugwiritsa ntchito

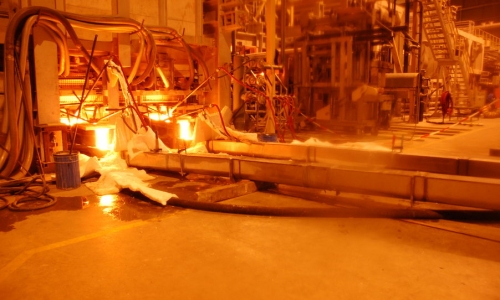

Makampani achitsulo ndi zitsulo:Amagwiritsidwa ntchito makamaka pakukonza ndi kuzigamba za ng'anjo zamagetsi zamagetsi, ng'anjo zopangira zitsulo, ma ladles ndi zida zina.

Makampani achitsulo osagwiritsa ntchito chitsulo:Amagwiritsidwa ntchito pazigamba ndi kukonza mkuwa, aluminiyamu, nthaka, faifi tambala ndi ng'anjo zina zopanda chitsulo zosungunula ndi zosinthira.

Makampani agalasi:Amagwiritsidwa ntchito pokonza ndi kukonza zigamba za ng'anjo zamagalasi, ng'anjo zamoto ndi zida zina.

Makampani opanga zida zomangira: Amagwiritsidwa ntchito pokonza ndi kukonza zida zopangira zida zomangira monga ng'anjo ya simenti yozungulira ndi gypsum kiln.

Makampani a Chemical:Amagwiritsidwa ntchito pokonza ndi kukonza zida zamagetsi zotentha kwambiri monga ng'anjo zong'ambika komanso zopangira gasifiri.

Makampani a Ceramic:Amagwiritsidwa ntchito pokonza ndi kukonza zida zopangira ceramic monga ng'anjo ya tunnel ndi ng'anjo ya shuttle.

Phukusi & Malo Osungira

Mafunso Ofunsidwa Kawirikawiri

Mukufuna thandizo?Onetsetsani kuti mwayendera mabwalo athu othandizira kuti mupeze mayankho a mafunso anu!

Ndife opanga zenizeni, fakitale yathu ndi yapadera popanga zida zokanira kwa zaka zopitilira 30.Timalonjeza kupereka mtengo wabwino kwambiri, ntchito yabwino kwambiri yogulitsiratu komanso yogulitsa pambuyo pake.

Panjira iliyonse yopanga, RBT ili ndi dongosolo lathunthu la QC la kapangidwe kake ndi zinthu zakuthupi.Ndipo tidzayesa katunduyo, ndipo chiphaso chabwino chidzatumizidwa ndi katunduyo.Ngati muli ndi zofunikira zapadera, tidzayesetsa kuti tikwaniritse.

Malingana ndi kuchuluka kwake, nthawi yathu yoperekera ndi yosiyana.Koma tikulonjeza kutumiza mwamsanga ndi khalidwe lotsimikizika.

Inde, timapereka zitsanzo zaulere.

Inde, ndithudi, ndinu olandiridwa kukaona RBT kampani ndi katundu wathu.

Palibe malire, titha kukupatsani malingaliro ndi yankho labwino kwambiri malinga ndi momwe mulili.

Takhala tikupanga zida zodzitchinjiriza kwa zaka zopitilira 30, tili ndi chithandizo champhamvu chaukadaulo komanso chidziwitso cholemera, titha kuthandiza makasitomala kupanga ma kilns osiyanasiyana ndikupereka ntchito imodzi.