Choumitsira cha Silicon Carbide

Magulu a Zamalonda

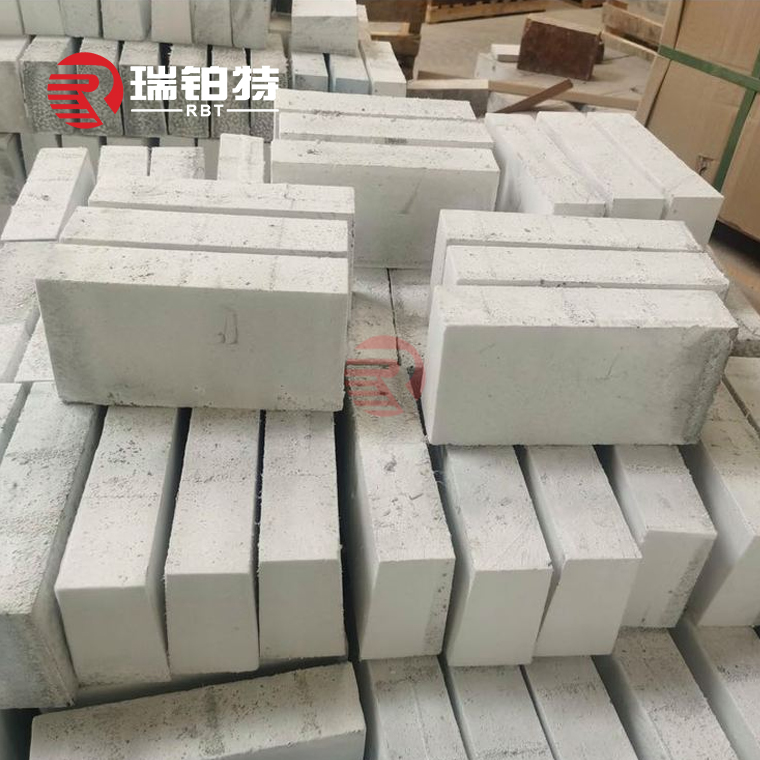

1. Zogulitsa za silicon carbide zomwe zimapangidwa ndi Reaction sintered (RBSiC Products)

Reaction bonded silicon carbide (RBSiC) ndi chida chapamwamba cha ceramic chomwe chimapanga gawo logwirizanitsa silicon carbide mwa kuchitapo kanthu ndi silicon yamadzimadzi pa kutentha kwakukulu. Zigawo zake zazikulu zimaphatikizapo matrix ya silicon carbide (SiC) ndi silicon yaulere (Si). Yoyamba imapereka mphamvu zabwino kwambiri zamakaniko, kukana kuwonongeka komanso kukhazikika kwa kutentha kwambiri,

pomwe chomalizachi chimadzaza ma pores pakati pa tinthu ta silicon carbide kuti chiwonjezere kuchulukana ndi kapangidwe kake.

(1) Makhalidwe:

Kukhazikika kwa kutentha kwakukulu:Kutentha kwakukulu kogwirira ntchito ndi 1350℃.

Kukana kuvala ndi kukana dzimbiri:Yoyenera kugwiritsidwa ntchito molimbika chifukwa cha kutentha kwambiri, asidi, alkali ndi chitsulo chosungunuka.

Kutentha kwakukulu komanso kutentha kochepa kwa coefficient:Mphamvu ya kutentha ndi yokwera kufika pa 120-200 W/(m·K), ndipo mphamvu ya kutentha ndi 4.5×10⁻⁶ K⁻¹ yokha, zomwe zimaletsa bwino ming'alu ya kutentha ndi kutopa kwa kutentha.

Anti-oxidation:Choteteza cha silika cholimba chimapangidwa pamwamba pa kutentha kwakukulu kuti chiwonjezere moyo wa ntchito.

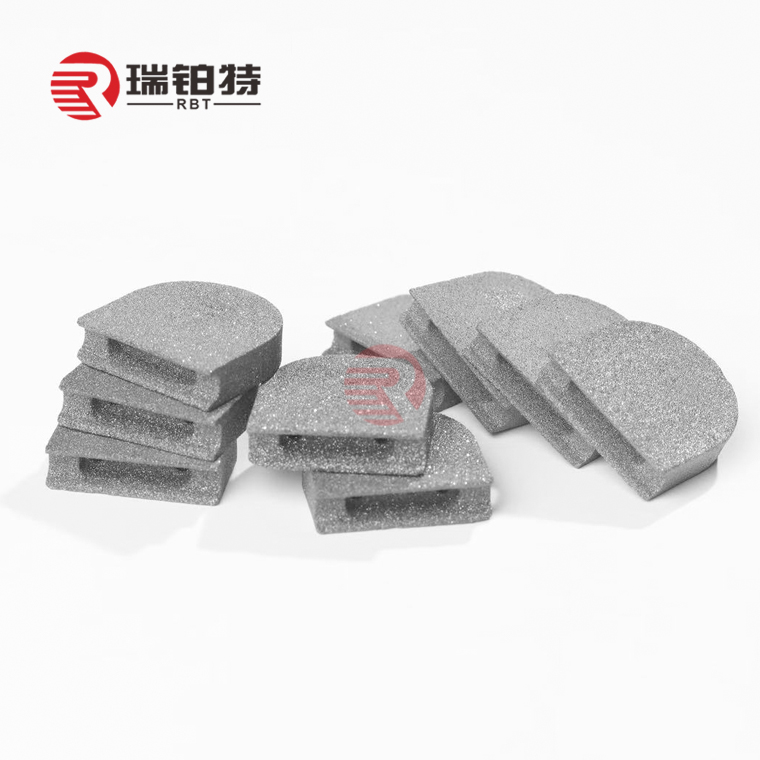

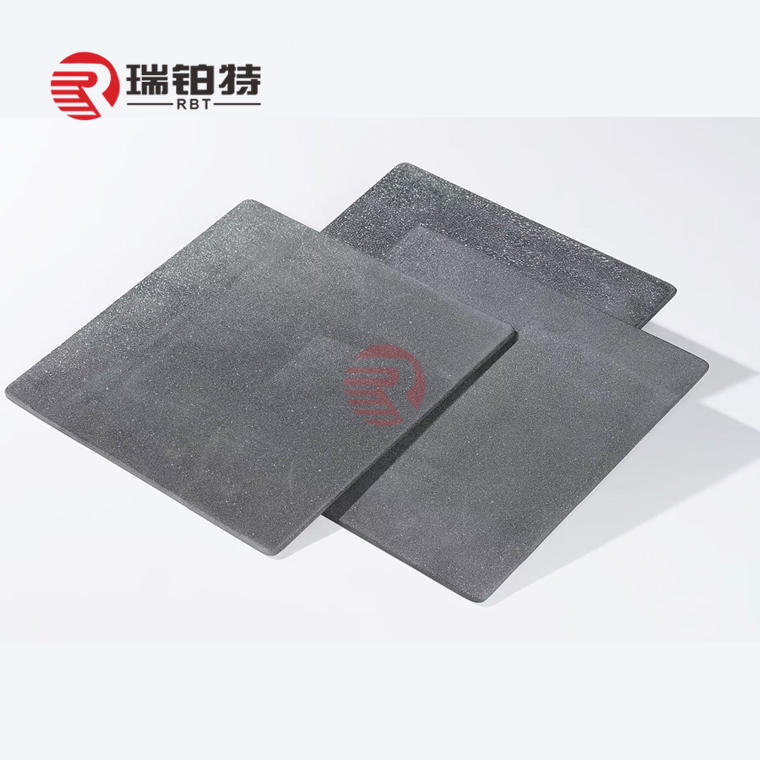

(2) Zogulitsa Zazikulu:

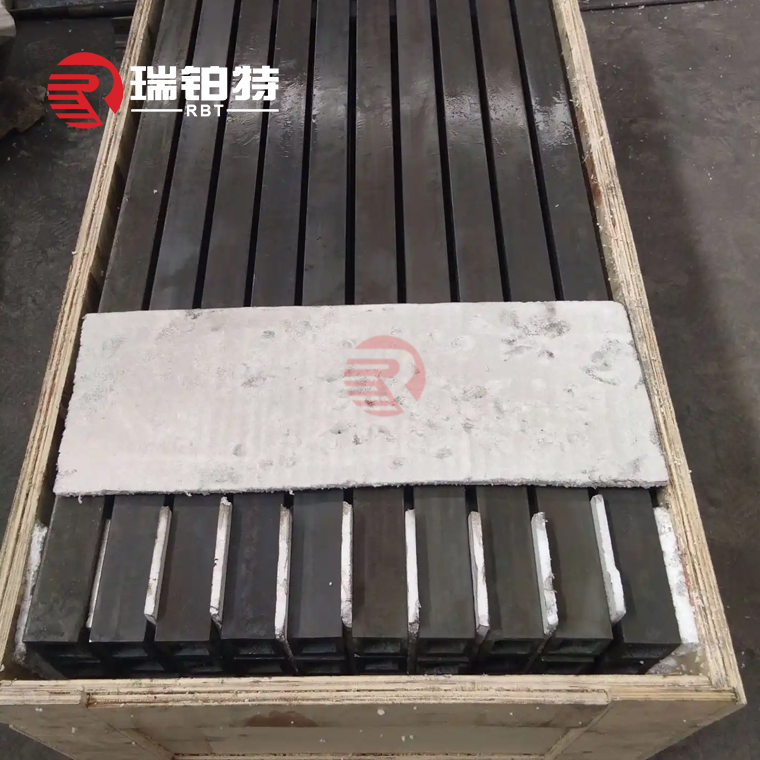

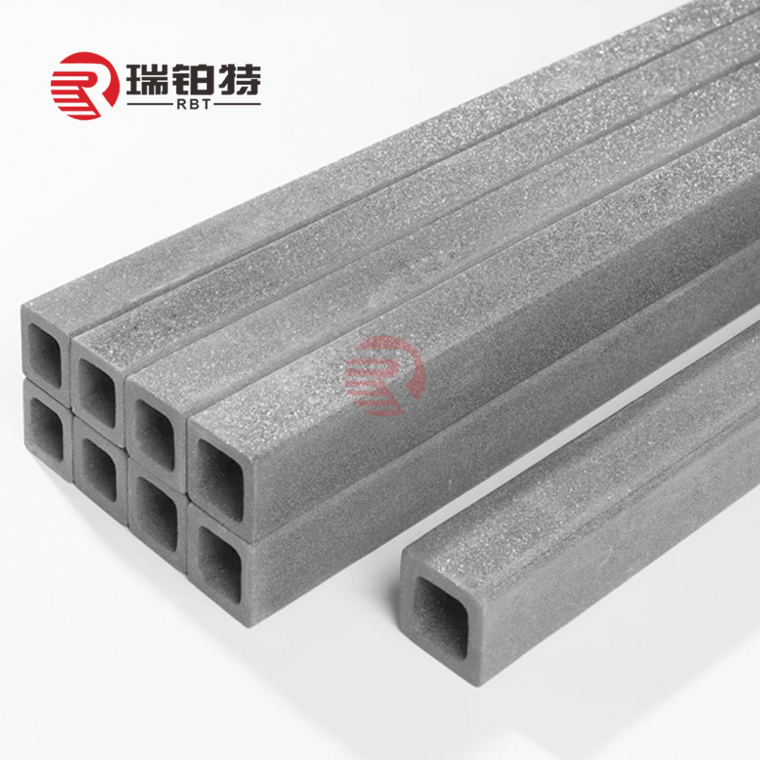

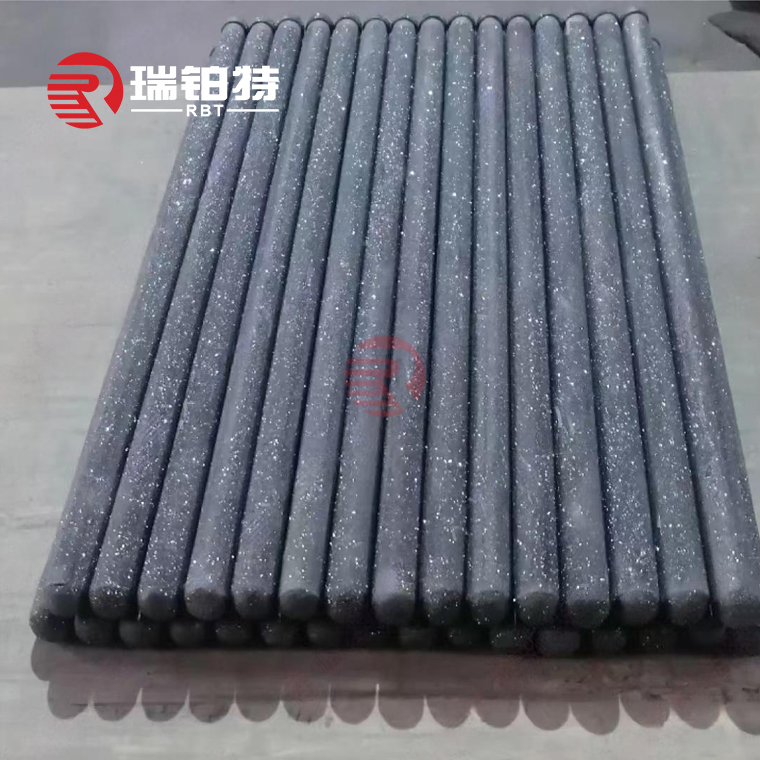

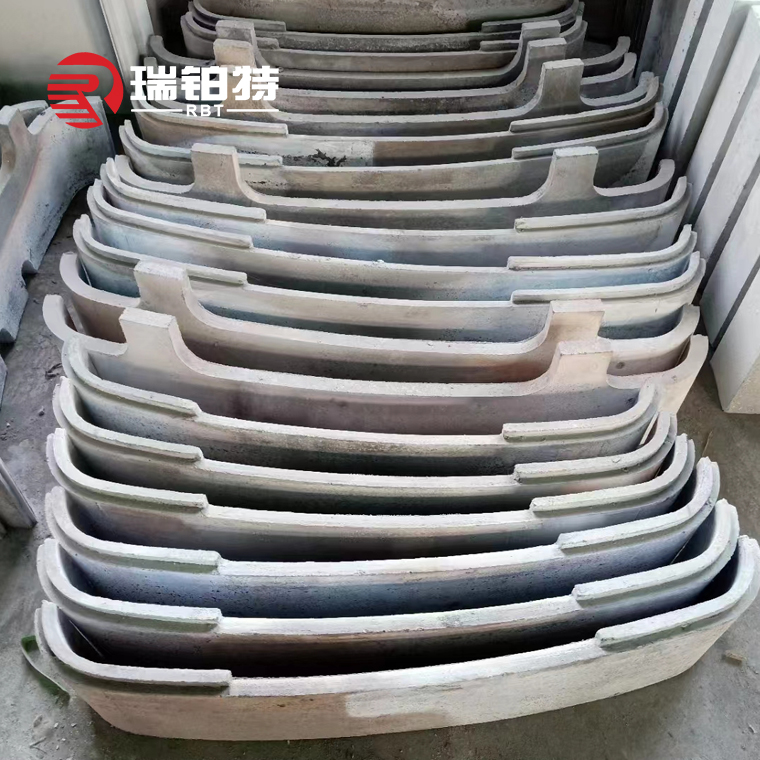

Mzere wa silicon carbide:imagwiritsidwa ntchito popanga ma kilns a tunnel, ma kilns a shuttle ndi ma kilns ena a mafakitale okhala ndi mphamvu zonyamula katundu, okhala ndi kukana kutentha kwambiri.

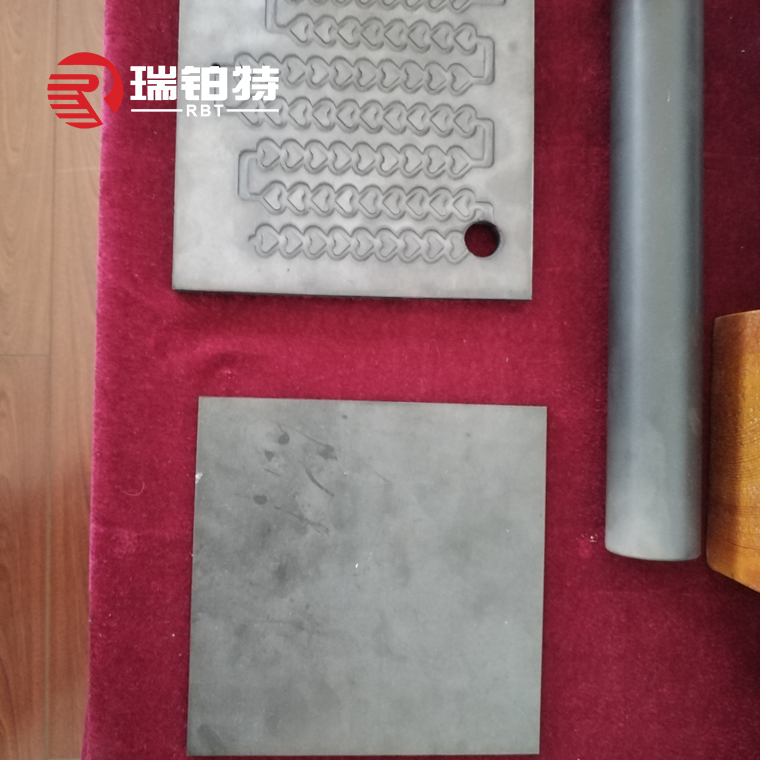

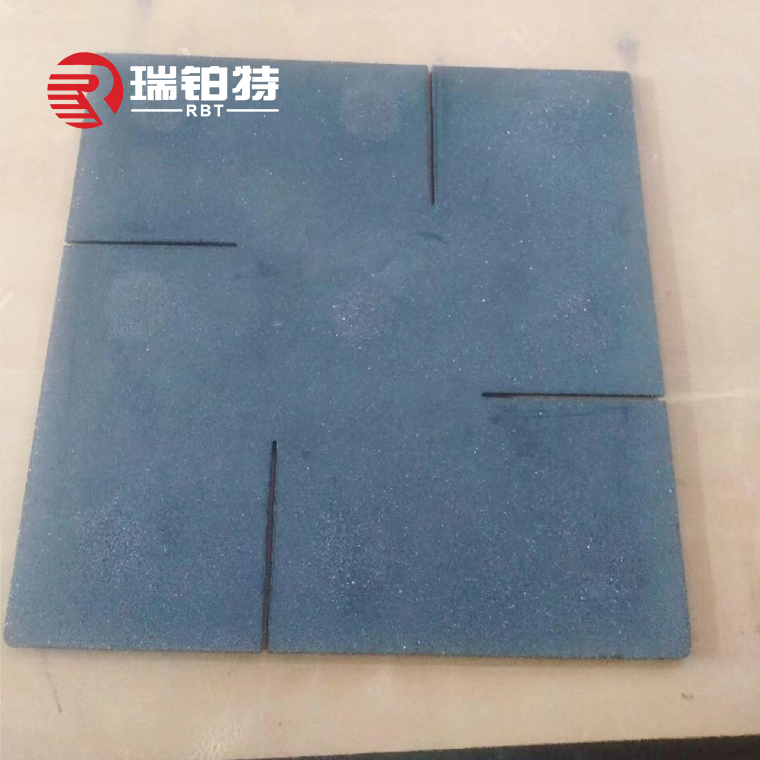

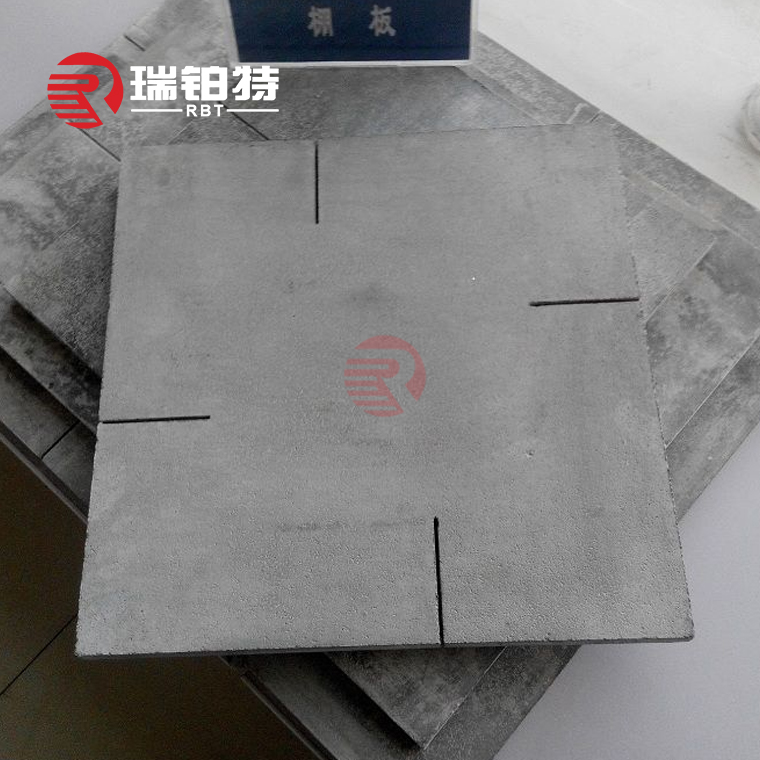

Mbale ya silicon carbide:amagwiritsidwa ntchito popanga zinthu zotsutsa mu uvuni, zomwe zimakhala ndi mawonekedwe a oxide bonding.

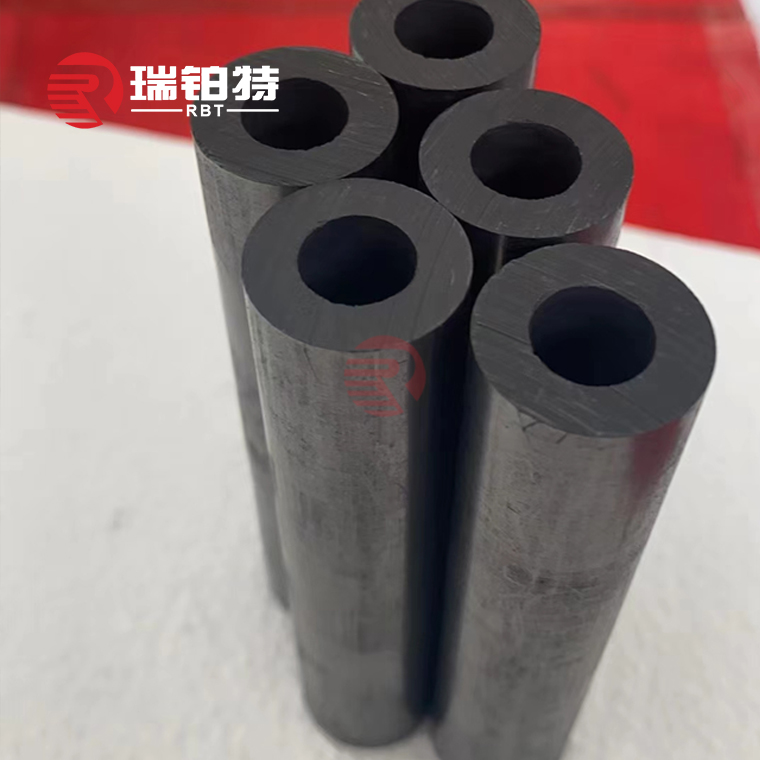

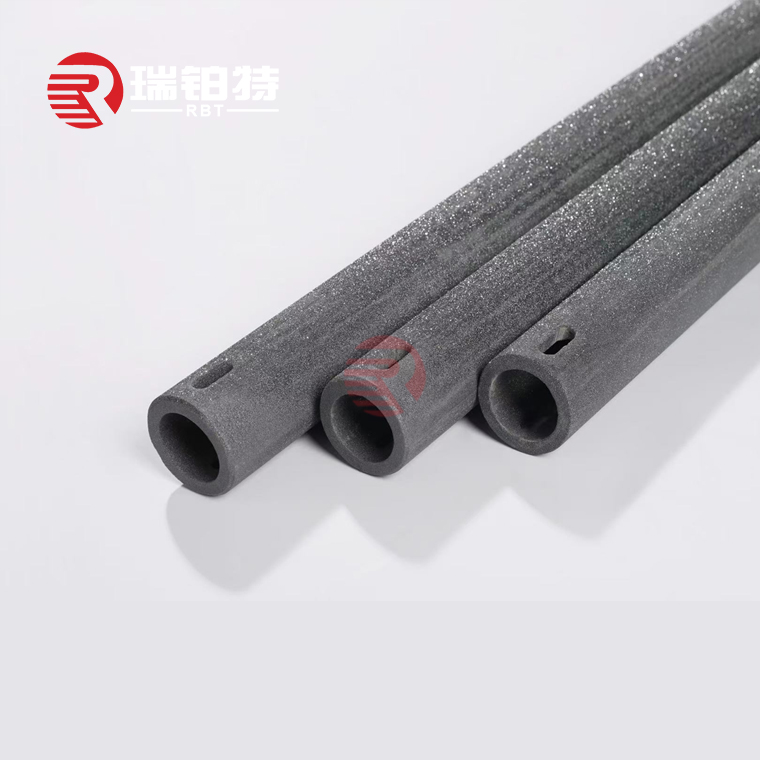

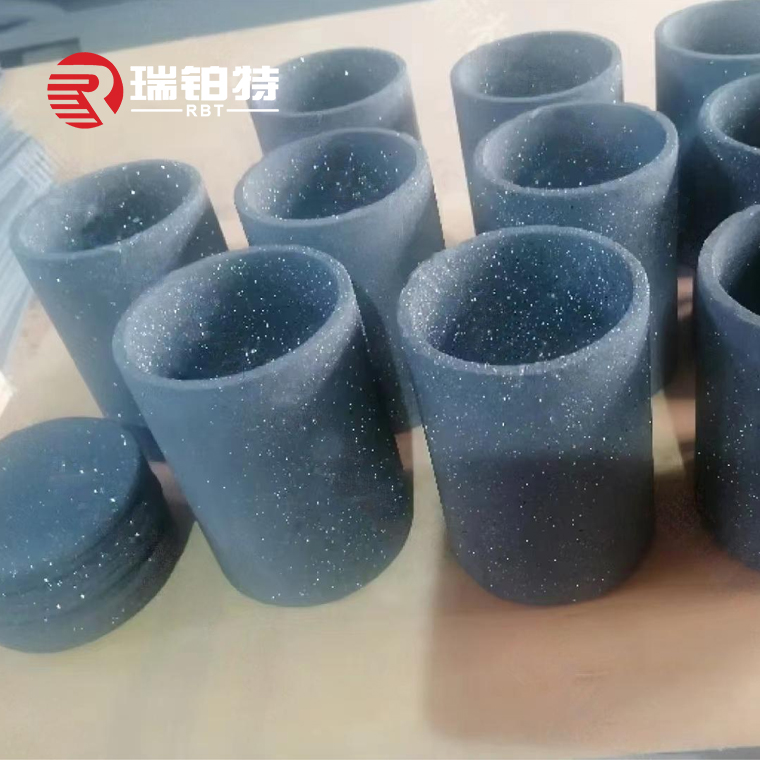

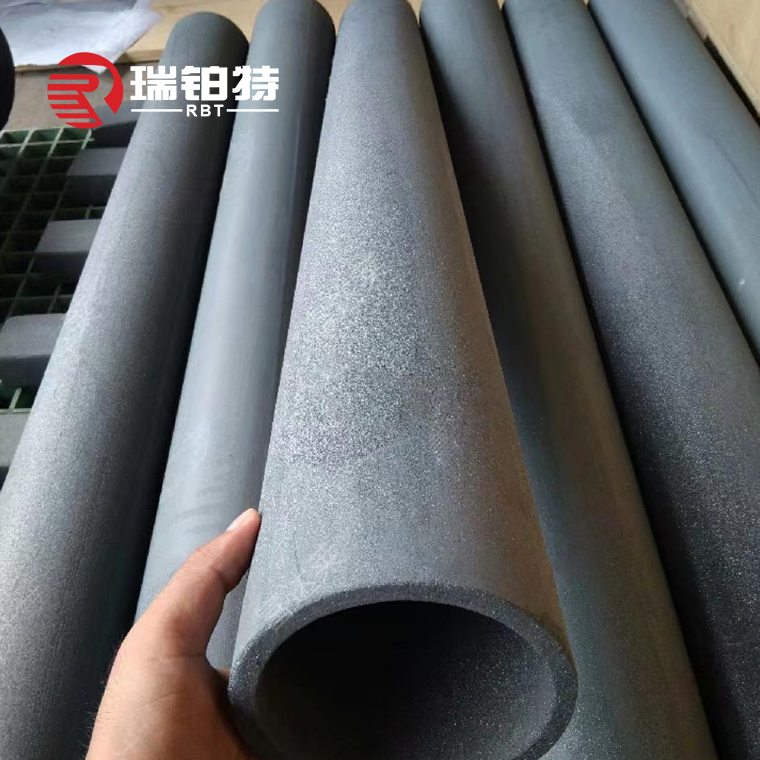

Chitoliro cha silicon carbide:amagwiritsidwa ntchito pa mapaipi ndi zotengera m'malo osiyanasiyana otentha kwambiri.

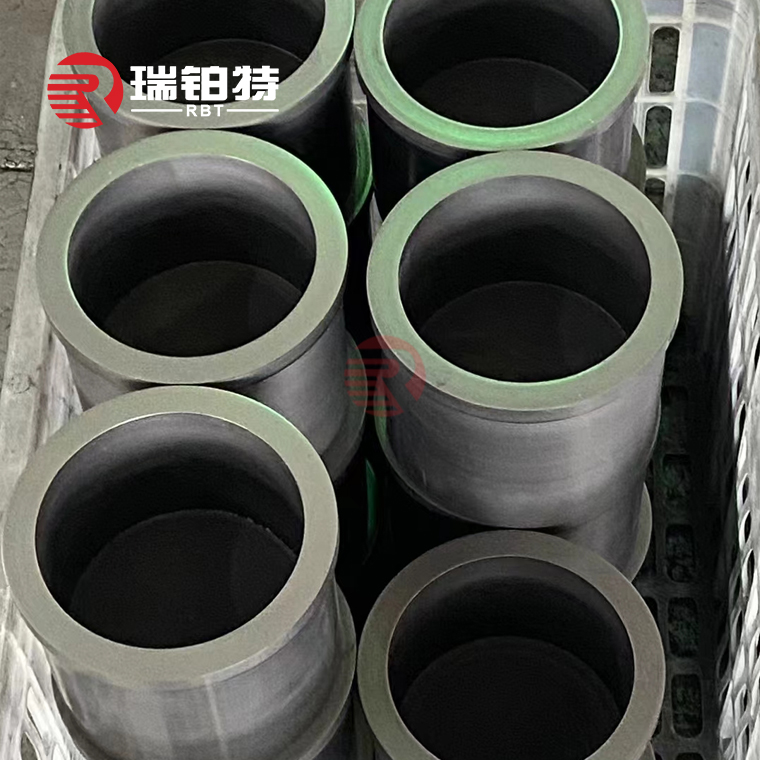

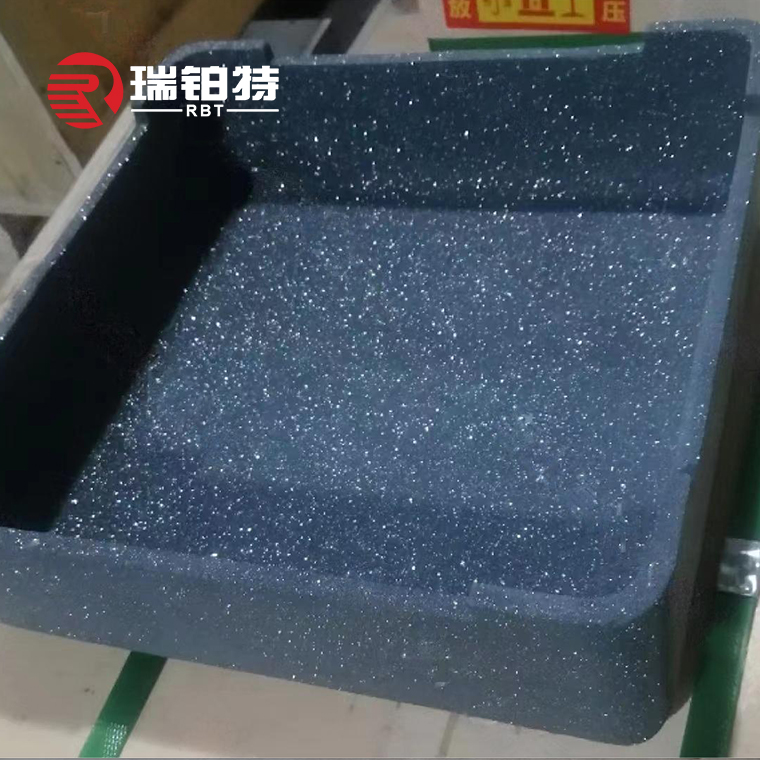

Chophimba cha silicon carbide ndi chozungulira:amagwiritsidwa ntchito posungunula ndi kusungira zinthu kutentha kwambiri.

Mphete yosindikizira ya silicon carbide:imagwiritsidwa ntchito kwambiri m'magawo a magalimoto, ndege ndi makampani opanga mankhwala, ndipo imatha kusunga magwiridwe antchito odalirika otsekera m'malo otentha kwambiri komanso opanikizika kwambiri.

Chozungulira cha silicon carbide:amagwiritsidwa ntchito pa ma roll kilns, okhala ndi makhalidwe oletsa okosijeni, mphamvu yosinthasintha kutentha kwambiri komanso moyo wautali wautumiki.

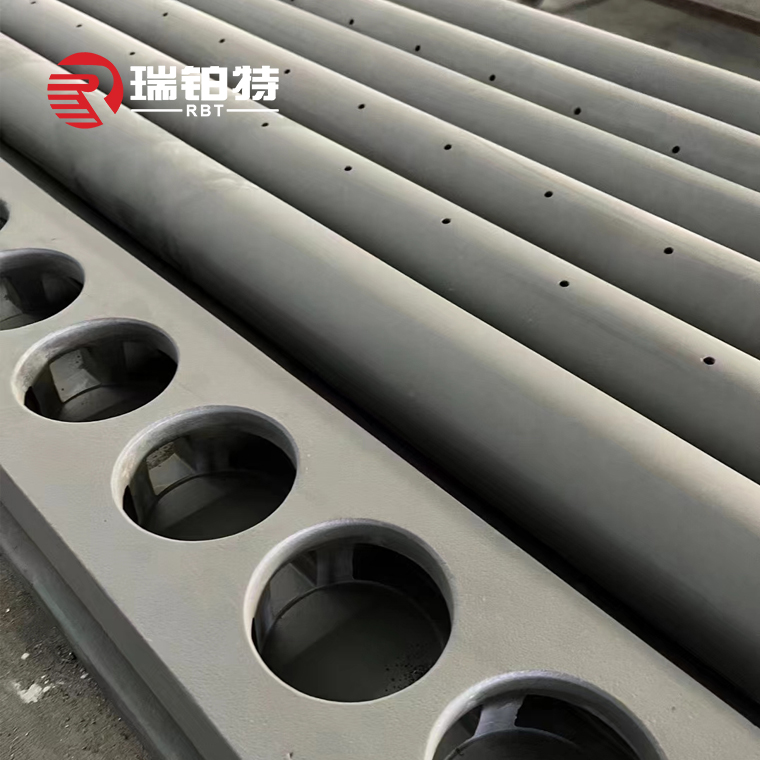

Mapaipi ozizira a silicon carbide:imagwiritsidwa ntchito poziziritsira ma roll kilns, ndipo imapirira bwino kwambiri

kuzizira ndi kutentha.

Silicon carbide bunner nozzle:amagwiritsidwa ntchito pa mafuta osiyanasiyana, gasi ndi ma uvuni ena a mafakitale, okhala ndi mawonekedwe a kukana kuzizira kwambiri ndi kutentha, kukana kukalamba, kukana kutentha kwambiri, ndi zina zotero.

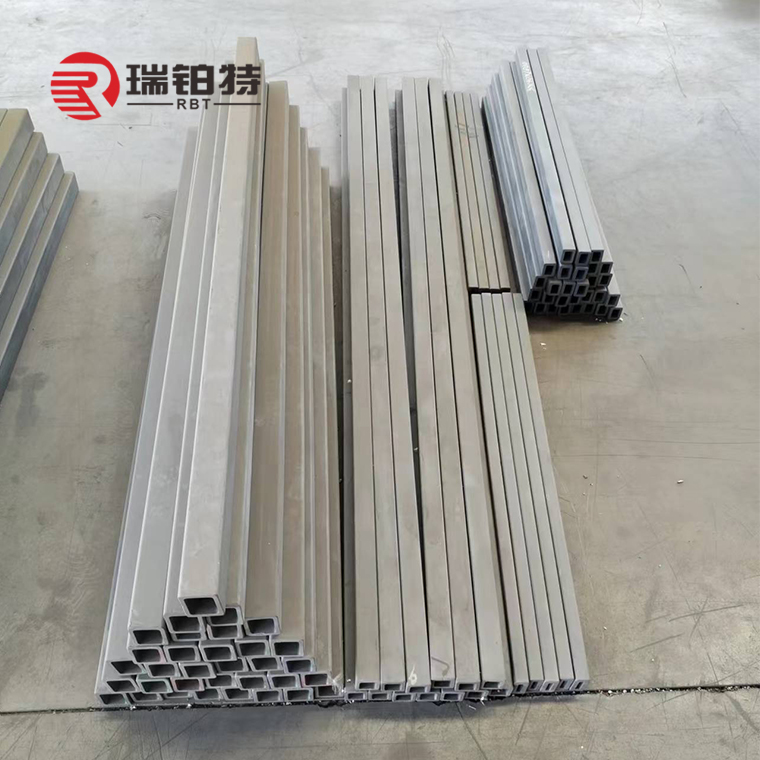

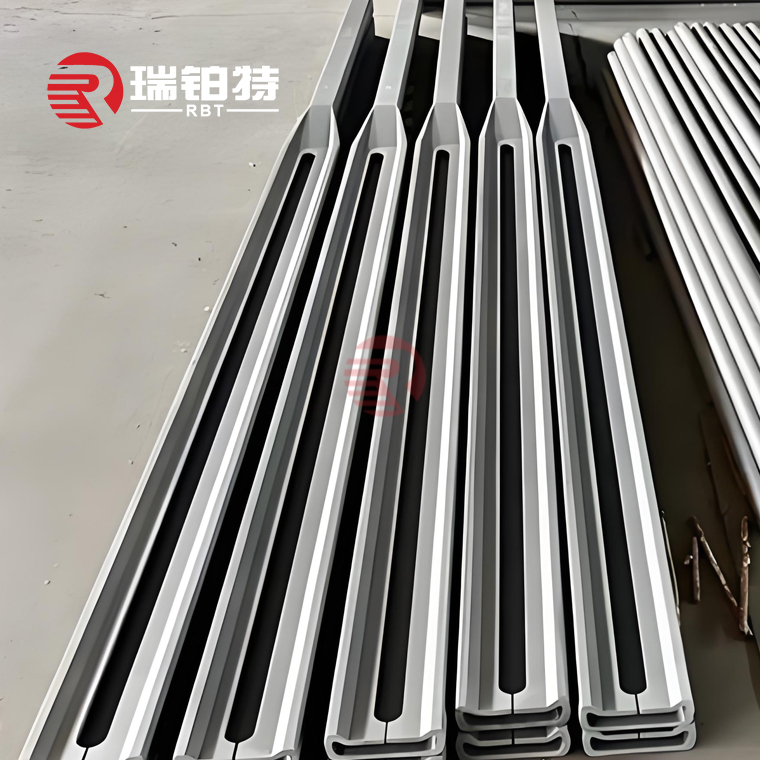

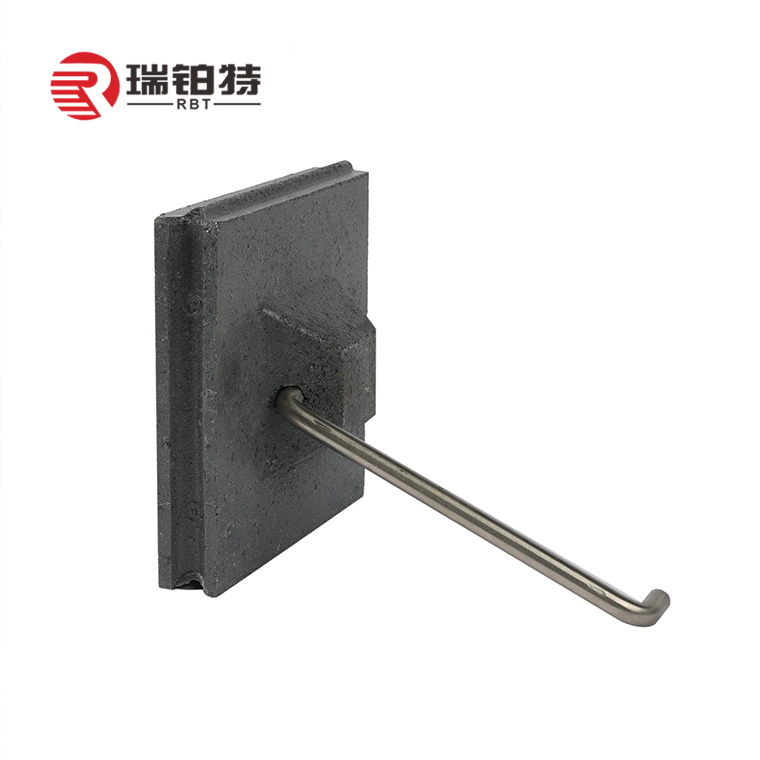

Magawo opangidwa mwapadera:Kupanga zinthu zosiyanasiyana zopangidwa ndi mawonekedwe apadera malinga ndi zosowa za makasitomala, monga mbale zooneka ngati nsomba, ndodo zopachikika, zida zothandizira, ndi zina zotero.

Zithunzi Zambiri

Mtanda wa Silicon Carbide

Silicon Carbide Cantilever Paddle

Silicon Carbide Nozzle

Silicon Carbide Burner chubu

Mapaipi Oziziritsa a Silicon Carbide

Silicon Carbide Nozzle

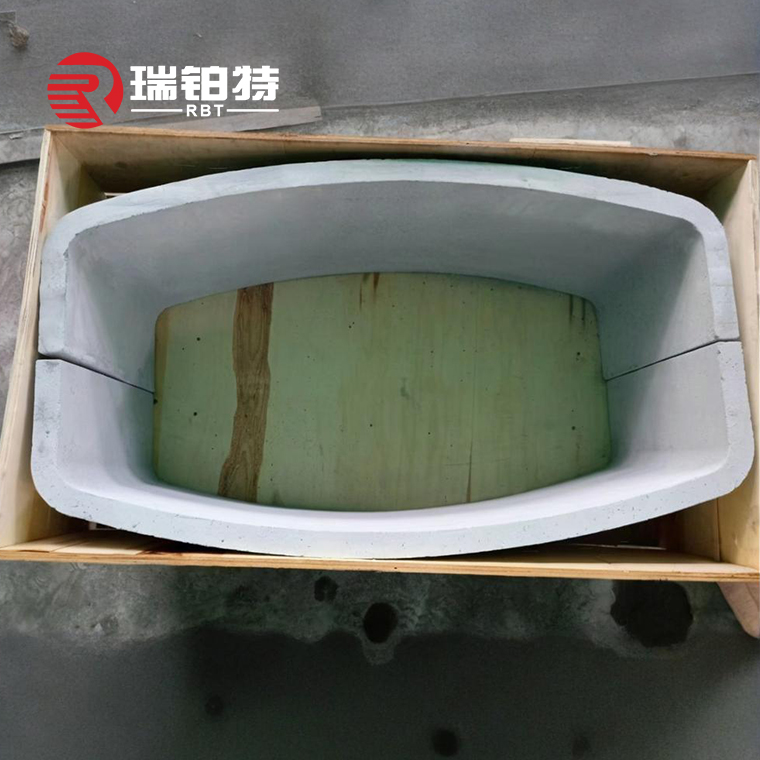

Chikwama cha Silikoni Carbide Boat

Mkati mwake wosavala

Boti la Silicon Carbide Wafer

Mndandanda wa Zamalonda

| Zogulitsa za RBSiC(SiSiC) | ||

| Chinthu | Chigawo | Deta |

| Kutentha Kwambiri kwa Ntchito | ℃ | ≤1350 |

| Kuchulukana | g/cm3 | ≥3.02 |

| Tsegulani Porosity | % | ≤0.1 |

| Mphamvu Yopindika | Mpa | 250(20℃); 280(1200℃) |

| Modulus of Elasticity | Gpa | 330(20℃); 300(1200℃) |

| Kutentha kwa Matenthedwe | W/mk | 45 (1200℃) |

| Kuchuluka kwa Kutentha | K-1*10-6 | 4.5 |

| Kuuma kwa Moh | | 9.15 |

| Asidi Yopanda Alkaline | | Zabwino kwambiri |

2. Zogulitsa za silicon carbide zopanda mphamvu zopanda mphamvu

Zinthu zopangidwa ndi silicon carbide zopanda kupanikizika ndi mtundu wa zinthu za ceramic zapamwamba zomwe zimapangidwa ndi njira yopangira sintering yopanda kupanikizika. Gawo lake lalikulu ndi silicon carbide (SiC), ndipo gawo lina la zowonjezera limawonjezedwa. Kudzera muukadaulo wapamwamba wa ceramic, imapangidwa kukhala zoumba za ceramic zopanda mabowo, zopanda msoko, komanso zopanda kupsinjika.

(1) Makhalidwe:

Kukana kutentha kwambiri:kugwiritsa ntchito bwino pa kutentha kwa 1800℃;

Kutentha kwambiri:zofanana ndi kutentha kwa graphitezipangizo;

Kuuma kwakukulu:Kuuma kwake ndi kwachiwiri kwa diamondi ndi cubic boron nitride;

Kukana dzimbiri:asidi wamphamvu ndi alkali wamphamvu sizimawononga, ndipo kukana kwake dzimbiri kuli bwino kuposa tungsten carbide ndi aluminiyamu oxide;

Kulemera kopepuka:kuchulukana kwa 3.10g/cm3, pafupi ndi aluminiyamu;

Palibe kusintha:coefficient yochepa kwambiri ya kutentha,

Yosagonjetsedwa ndi kutentha:Zinthuzo zimatha kupirira kusintha kwa kutentha mwachangu, kutentha kwambiri, kuzizira mwachangu komanso kutentha, ndipo zimakhala ndi magwiridwe antchito okhazikika.

(2) Zogulitsa Zazikulu:

Mphete zosindikizira:Zinthu zopangidwa ndi silicon carbide zopanda mphamvu nthawi zambiri zimagwiritsidwa ntchito popanga mphete zotsekera komanso zotchingira zosasunthika komanso zosagwirizana ndi dzimbiri.

Zigawo za makina:Kuphatikizapo mabearing otentha kwambiri, zisindikizo zamakina, ma nozzles, ma valve a pneumatic, matupi a pampu, zida zolumikizira, ndi zina zotero.

Zipangizo za Chemical:Amagwiritsidwa ntchito popanga mapaipi osapsa ndi dzimbiri, matanki osungiramo zinthu, ma reactor ndi zisindikizo.

Zipangizo zamagetsi:Mu makampani opanga magetsi, silicon carbide yopanda mphamvu imagwiritsidwa ntchito popanga zotsutsana ndi kutentha kwambiri, zinthu zotenthetsera zamagetsi ndi maswichi amphamvu kwambiri.

Mipando ya Kiln:Monga mafelemu onyamula katundu, ma rollers, ma nozzles a moto, mapaipi ozizira, ndi zina zotero. m'ma ng'anjo za ngalande, ma shuttle kilns ndi ma ng'anjo ena a mafakitale.

Zithunzi Zambiri

Mphete Yosindikizira ya Silicon Carbide

Chitoliro cha Silicon Carbide

Zitsulo za Silicon Carbide

Mtanda wa Silicon Carbide

Mbale ya Silicon Carbide

Mbiya Yopera ya Silicon Carbide

Mndandanda wa Zamalonda

| Zogulitsa za SSiC | ||

| Chinthu | Chigawo | Zotsatira |

| Kuuma | HS | ≥115 |

| Chiŵerengero cha Kuyenda kwa Miyendo | % | <0.2 |

| Kuchulukana | g/cm3 | ≥3.10 |

| Mphamvu Yokakamiza | Mpa | ≥2500 |

| Mphamvu Yopindika | Mpa | ≥380 |

| Kuchuluka kwa Kukula | 10-6/℃ | 4.2 |

| Zomwe zili mu SiC | % | ≥98 |

| Si Yaulere | % | <1 |

| Modulus Yotanuka | Gpa | ≥410 |

| Kutentha Kwambiri kwa Ntchito | ℃ | 1400 |

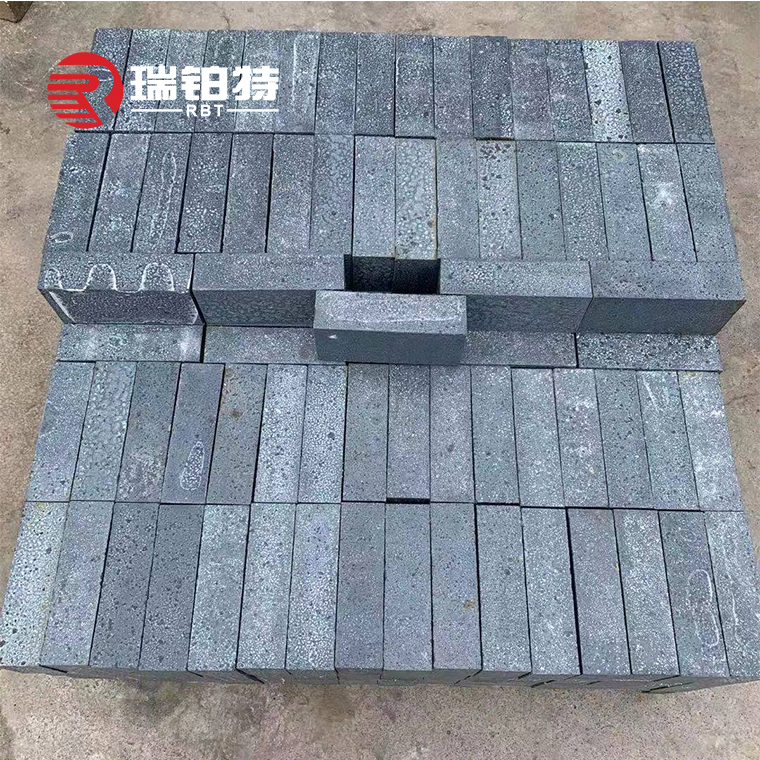

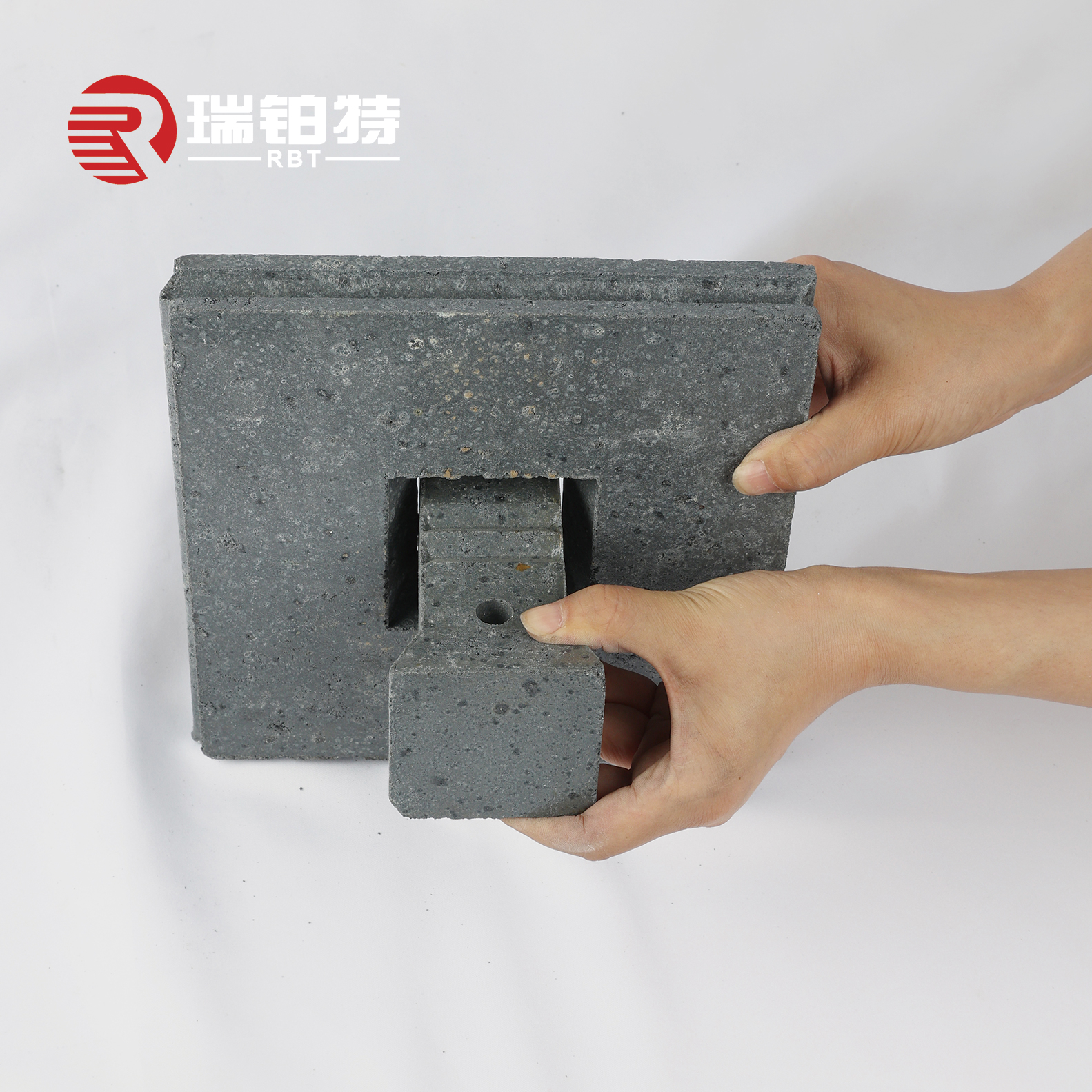

3. Chogulitsa cha silicon carbide chobwezeretsedwanso (Zogulitsa za RSiC)

Zopangidwa ndi Silicon Carbide Zobwezeretsedwanso ndi chinthu chopanda mphamvu chopangidwa ndi silicon carbide yoyera kwambiri ngati zopangira. Mbali yake yayikulu ndi yakuti palibe gawo lachiwiri ndipo limapangidwa ndi 100% α-SiC.

(1) Makhalidwe:

Kuuma kwakukulu:Kuuma kwake ndi kwachiwiri kuposa diamondi, ndipo kuli ndi mphamvu zambiri zamakanika komanso kulimba kwake.

Kukana kutentha kwambiri:Imatha kukhalabe ndi magwiridwe antchito okhazikika pamalo otentha kwambiri ndipo ndi yoyenera kutentha kwa 1350 ~ 1600℃.

Kukana kwamphamvu kwa dzimbiri:Ili ndi kukana dzimbiri kwambiri ku mitundu yosiyanasiyana ya zinthu ndipo imatha kusungamphamvu zamakina kwa nthawi yayitali m'malo osiyanasiyana owononga.

Kukana bwino kwa oxidation:Ili ndi kukana kwabwino kwa okosijeni ndipo imatha kugwira ntchito bwino kutentha kwambiri.

Kukana bwino kutentha kwa kutentha:Imagwira ntchito bwino pamalo omwe kutentha kumasintha mofulumira ndipo ndi yoyenera malo omwe kutentha kumagwedezeka.

Palibe kufooka panthawi yochita opaleshoni:Sichichepa panthawi yokonza zinthu, ndipo palibe kupsinjika komwe kudzapangidwe komwe kungachititse kuti chinthucho chisinthe kapena kusweka. Ndikoyenera kukonzekera zigawo zokhala ndi mawonekedwe ovuta komanso olondola kwambiri.

(2) Zogulitsa Zazikulu:

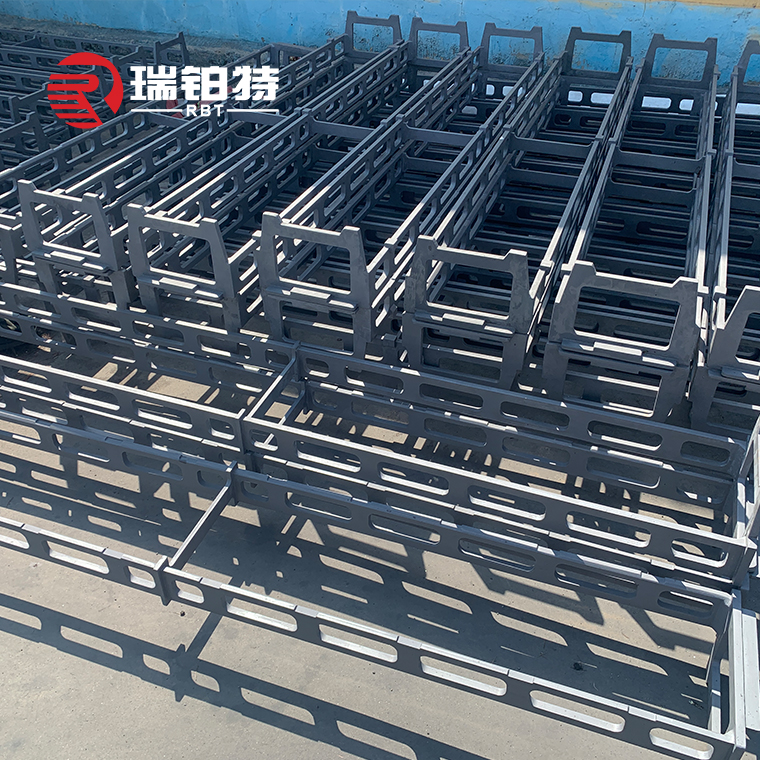

Zipangizo za mipando ya mu uvuni:Imagwiritsidwa ntchito makamaka pa mipando ya uvuni, ili ndi ubwino wosunga mphamvu, kuwonjezera kuchuluka kwa uvuni, kufupikitsa nthawi yoyatsira moto, kukonza bwino ntchito yopangira uvuni komanso phindu lalikulu pazachuma.

Ma nozzles a Bunner:Itha kugwiritsidwa ntchito ngati mitu ya nozzle yoyaka ndipo ndi yoyenera malo otentha kwambiri.

Machubu otenthetsera a Ceramic radiation:Machubu otenthetsera awa amagwiritsa ntchito kukhazikika kwa kutentha kwambiri komanso kukana dzimbiri kwa silicon carbide yobwezeretsedwanso ndipo ndi oyenera kugwiritsidwa ntchito m'mafakitale osiyanasiyana otentha kwambiri.

Machubu oteteza zinthu:Makamaka m'zitofu zamlengalenga, zinthu zopangidwa ndi silicon carbide zomwe zimabwezedwanso zimagwiritsidwa ntchito ngati machubu oteteza zinthu zomwe zimakhala ndi kutentha kwakukulu komanso kukana dzimbiri.

Mabomba a pampu otentha kwambiri, ma impeller a pampu, ma bearing, ndi ma housings a injini:M'magawo a magalimoto, ndege ndi mafakitale ankhondo, zipangizo za silicon carbide zobwezeretsedwanso zimapangidwa kukhala matupi a mapampu otentha kwambiri, ma impeller a pampu, ma bearing ndi ma housings a injini, ndi zina zotero, pogwiritsa ntchito mwayi wawo wokana kutentha kwambiri, kukana asidi ndi dzimbiri la alkali komanso kukana kuvala.

Zithunzi Zambiri

Mbali Zooneka ndi Silicon Carbide

Mbale ya Silicon Carbide

Silicon Carbide Roller

Mtanda wa Silicon Carbide

Machubu Oteteza a Silicon Carbide

Mipando ya uvuni

Silikoni Carbide Sagger

Silikoni Carbide Crucible

Mbale ya Silicon Carbide

Silicon Carbide Lgniter

Chitoliro cha Silicon Carbide

Choyatsira Kabide cha Silicon

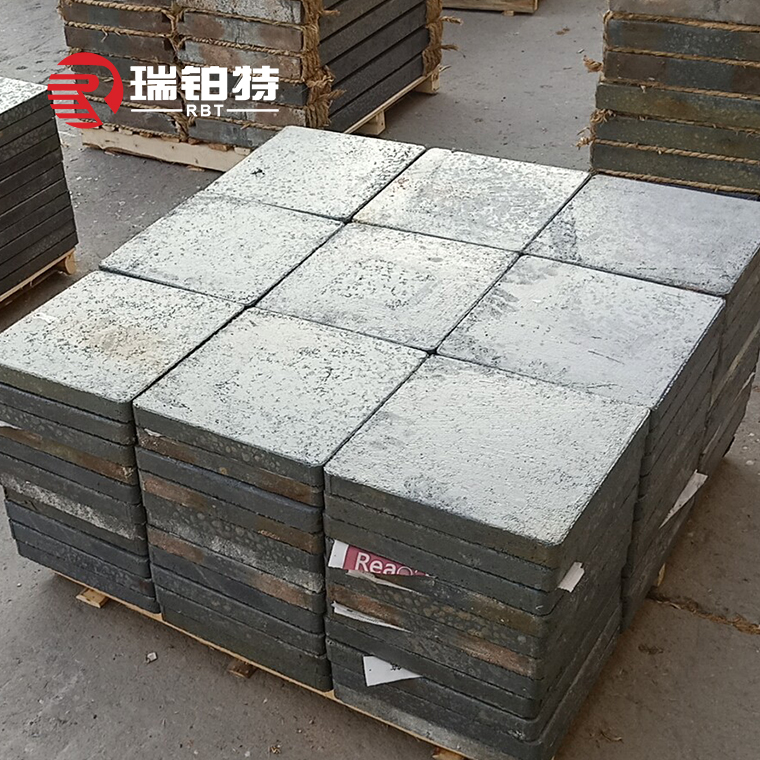

4. Zogulitsa za silicon carbide zolumikizidwa ndi silicon nitride (Zogulitsa za NSiC)

Zogulitsa za silicon carbide zolumikizidwa ndi silicon nitride ndi zinthu zopangidwa powonjezera SiC aggregate ku ufa wa silicon wa mafakitale, zomwe zimakumana ndi nayitrogeni pa kutentha kwakukulu kuti zipange Si3N4 ndikusakanikirana mwamphamvu ndi tinthu ta SiC.

(1) Makhalidwe:

Kuuma kwakukulu:Kuuma kwa Mohs kwa zinthu zopangidwa ndi silicon nitride bonded silicon carbide kuli pafupifupi 9, kwachiwiri pambuyo pa diamondi, ndipo ndi chinthu chokhala ndi kuuma kwakukulu pakati pa zinthu zopanda chitsulo.

Mphamvu ya kutentha kwambiri:Pa kutentha kwakukulu kwa 1200-1400℃, mphamvu ndi kuuma kwa chinthucho sizisintha kwenikweni, ndipo kutentha kwakukulu kogwiritsidwa ntchito motetezeka kumatha kufika 1650-1750℃.

Kukhazikika kwa kutentha:Ili ndi mphamvu yocheperako yokulitsa kutentha komanso mphamvu yotulutsa kutentha kwambiri, sikophweka kupanga kupsinjika kwa kutentha, ili ndi kukhazikika kwa kutentha komanso kukana kugwedezeka, ndipo ndi yoyenera malo ozizira kwambiri komanso otentha kwambiri.

Kukhazikika kwa mankhwala:Ndi yolimba ndi dzimbiri komanso yolimba ndi okosijeni, ndipo imatha kukhala yokhazikika m'malo osiyanasiyana a mankhwala.

Kukana kuvala:Ili ndi kukana kuvala bwino ndipo ndi yoyenera kugwiritsidwa ntchito m'mafakitale osiyanasiyana omwe amawonongeka kwambiri.

(2) Zogulitsa Zazikulu:

Njerwa zosagwira ntchito:amagwiritsidwa ntchito kwambiri mu aluminiyamu yamagetsi, ng'anjo zopangira zitsulo, ng'anjo zozungulira pansi pa nthaka ndi mafakitale ena, okhala ndi mawonekedwe okana kutentha kwambiri, kukana dzimbiri, komanso kukana kukokoloka kwa nthaka.

Mipando ya uvuni:amagwiritsidwa ntchito popangira mawilo opukutira a ceramic, porcelain yamagetsi yamagetsi amphamvu kwambiri, ma uvuni amafakitale, ndi zina zotero, okhala ndi mphamvu yabwino yonyamula katundu komanso kukana kutentha kwambiri.

Zogulitsa zopangidwa ndi mawonekedwe apadera:amagwiritsidwa ntchito popanga zitsulo zopanda chitsulo, mphamvu ya kutentha, ng'anjo zolowa pansi pa nthaka ndi mafakitale ena, okhala ndi mawonekedwe okana kuwonongeka ndi kukana kutentha kwambiri.

Zigawo zotsutsa:kuphatikizapo machubu oteteza thermocouple, machubu okweza, manja otenthetsera, ndi zina zotero, zomwe zimagwiritsidwa ntchito mu uvuni wotentha kwambiri komanso m'mlengalenga wosiyanasiyana, wokhala ndi kutentha kwambiri komanso kukana dzimbiri.

Zithunzi Zambiri

Mbale Yokhala ndi Kaliboni Yokhala ndi Kaliboni

Mbale Yokhala ndi Kaliboni Yokhala ndi Kaliboni

Mbale Yokhala ndi Kaliboni Yokhala ndi Kaliboni

Mbale Yokhala ndi Kaliboni Yokhala ndi Kaliboni

Mbale Yokhala ndi Kaliboni Yokhala ndi Kaliboni

Machubu a Radiation a Silicon Carbide

Chitoliro cha Silicon Carbide

Mbale Yokhala ndi Kaliboni Yokhala ndi Kaliboni

Mbali Zooneka ndi Silicon Carbide

Machubu Oteteza a Silicon Carbide

Mbale ya Silicon Carbide

Njerwa za Silicon Carbide

5. Zogulitsa za silicon carbide zolumikizidwa ndi oxide

Zinthu zopangidwa ndi silicon carbide zolumikizidwa ndi oxide zimapangidwa posakaniza tinthu ta silicon carbide ndi ufa wa oxide (monga silicon dioxide kapena mullite), kukanikiza ndi kusungunula pa kutentha kwakukulu. Khalidwe lake ndilakuti panthawi yosungunula ndi kugwiritsa ntchito, filimu ya oxide imakulungidwa pa tinthu ta silicon carbide, zomwe zimapangitsa kuti kukana kwa okosijeni kukhale kolimba komanso kulimba kwa kutentha kwambiri.

Ili ndi mphamvu yosinthasintha kutentha kwambiri, kukhazikika bwino pa kutentha, kutentha kwambiri, kukana kuwonongeka komanso kukana kwambiri kukokoloka kwa mlengalenga, ndipo ndi chinthu chabwino kwambiri chosungira mphamvu m'mafakitale.

(2) Zogulitsa Zazikulu:

Zinthu za silicon carbide zomwe zimapangidwa ndi silicon dioxide:Chogulitsachi chimagwiritsa ntchito silicon dioxide (SiO2) ngati gawo lomangirira. Nthawi zambiri 5% ~ 10% ya ufa wa silicon dioxide kapena ufa wa quartz umasakanizidwa ndi tinthu ta silicon carbide (SiC). Nthawi zina flux imawonjezeredwa. Pambuyo pokanikiza ndi kupanga, imawotchedwa mu uvuni wamba. Khalidwe lake ndilakuti panthawi yowotcha ndikugwiritsa ntchito, filimu ya silicon dioxide imakulungidwa pa tinthu ta silicon carbide, zomwe zimapangitsa kuti kukana kwa okosijeni kukhale bwino komanso mphamvu ya kutentha kwambiri. Chogulitsachi chimagwiritsidwa ntchito kwambiri m'mashelufu a uvuni powotcha porcelain (>1300℃), ndipo nthawi yake yogwira ntchito ndi yoposa

kuwirikiza kawiri kuposa zinthu zopangidwa ndi silicon carbide zomangidwa ndi dongo.

Zinthu zopangidwa ndi silicon carbide zolumikizidwa ndi ma bond ambiri:Chogulitsachi chimawonjezera ufa wa α-Al2O3 ndi ufa wa silicon dioxide ku zosakaniza za silicon carbide. Pambuyo pokanikiza ndi kupanga, Al2O3 ndi SiO2 zimaphatikizidwa kuti zipange mullite panthawi yopopera. Pakagwiritsidwa ntchito, silicon dioxide yopangidwa ndi okosijeni wa silicon carbide imapanga pang'ono mullite ndi Al2O3. Chipangizochi chili ndi kukhazikika kwa kutentha ndipo chimagwiritsidwa ntchito kwambiri popanga ma saggers a porcelain ndi mashelufu.

Zithunzi Zambiri

Mbale ya Silicon Carbide

Njerwa za Silicon Carbide

Mbale ya Silicon Carbide

Chitoliro cha SiC Microcrystalline

Bodi ya SiC Microcrystalline

Bodi ya SiC Microcrystalline

Mbiri Yakampani

Shandong Robert New Material Co., Ltd.ili ku Zibo City, Shandong Province, China, komwe ndi malo opangira zinthu zopinga. Ndife kampani yamakono yomwe imagwirizanitsa kafukufuku ndi chitukuko, kupanga, kugulitsa, kapangidwe ndi zomangamanga za uvuni, ukadaulo, ndi kutumiza zinthu zopinga. Tili ndi zida zonse, ukadaulo wapamwamba, mphamvu yaukadaulo yamphamvu, khalidwe labwino kwambiri la malonda, komanso mbiri yabwino. Fakitale yathu imakwirira maekala opitilira 200 ndipo kutulutsa kwapachaka kwa zinthu zopinga ndi pafupifupi matani 30000 ndipo zinthu zopinga ndi matani 12000.

Zinthu zathu zazikulu zopangidwa ndi zinthu zotsutsa ndi izi:zipangizo zotsukira za alkaline; zipangizo zotsukira za silikoni ya aluminiyamu; zipangizo zosaoneka ngati zotsukira; zipangizo zotenthetsera kutentha; zipangizo zapadera zotsukira; zipangizo zogwirira ntchito zotsukira za makina opitira patsogolo.

Mafunso Ofunsidwa Kawirikawiri

Mukufuna thandizo? Onetsetsani kuti mwapita ku malo athu othandizira kuti mupeze mayankho a mafunso anu!

Ndife opanga enieni, fakitale yathu yakhala ikupanga zinthu zotsutsa kwa zaka zoposa 30. Tikulonjeza kupereka mtengo wabwino kwambiri, ntchito yabwino kwambiri yogulitsa zinthu zisanagulitsidwe komanso zitagulitsidwa.

Pa njira iliyonse yopangira, RBT ili ndi dongosolo lathunthu la QC la kapangidwe ka mankhwala ndi mawonekedwe ake. Ndipo tidzayesa katunduyo, ndipo satifiketi yaubwino idzatumizidwa ndi katunduyo. Ngati muli ndi zofunikira zapadera, tidzayesetsa momwe tingathere kuti zigwirizane nazo.

Kutengera kuchuluka kwa katundu, nthawi yathu yotumizira ndi yosiyana. Koma tikulonjeza kutumiza mwachangu momwe tingathere ndi mtundu wotsimikizika.

Inde, timapereka zitsanzo zaulere.

Inde, ndithudi, mwalandiridwa kupita ku kampani ya RBT ndi zinthu zathu.

Palibe malire, titha kupereka malingaliro abwino kwambiri komanso yankho malinga ndi momwe zinthu zilili.

Takhala tikupanga zinthu zopinga kwa zaka zoposa 30, tili ndi chithandizo champhamvu chaukadaulo komanso chidziwitso chambiri, titha kuthandiza makasitomala kupanga ma uvuni osiyanasiyana ndikupereka chithandizo chimodzi chokha.