Alumina Lining Plates

Gulu lazinthu

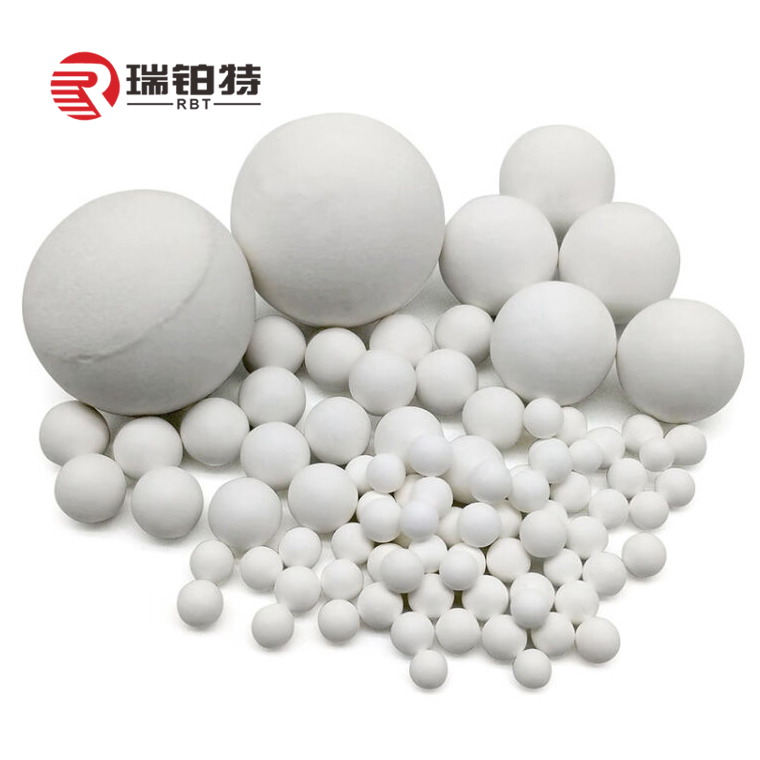

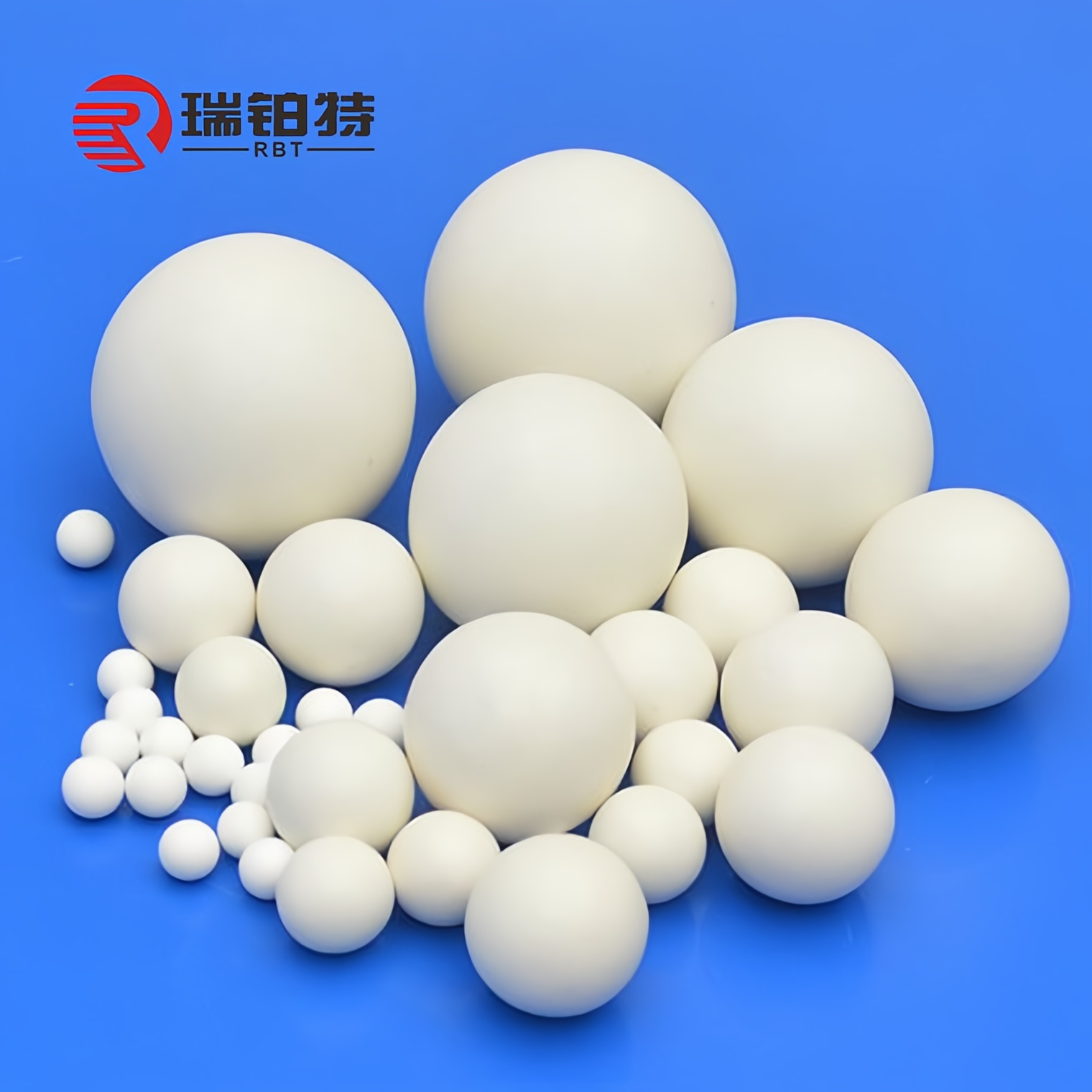

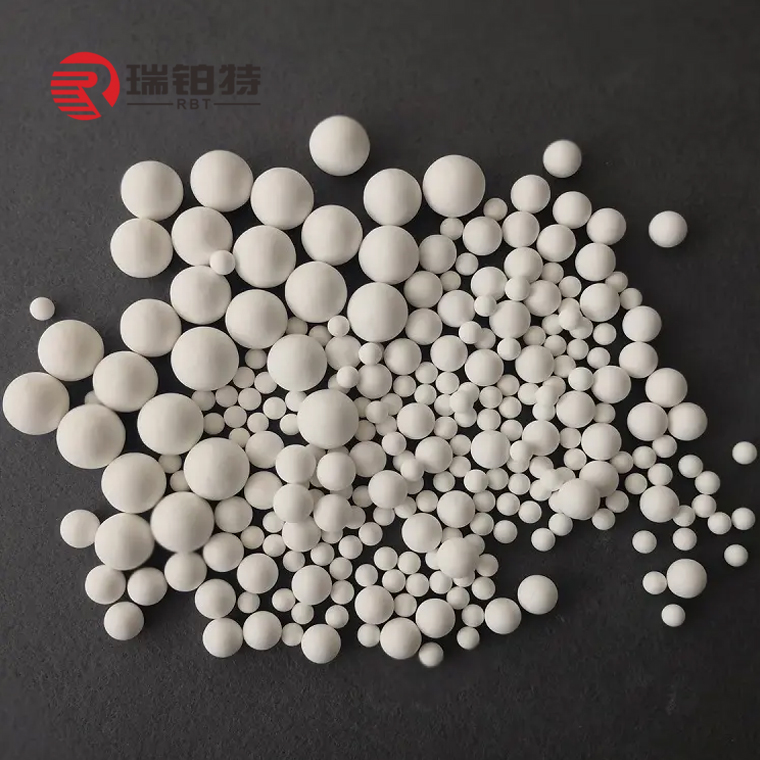

1. Mpira wa Alumina

(1) Mipira ya aluminiyamu ya ceramicndi apamwamba-ntchito inorganic sanali zitsulo zakuthupi ndi aluminium okusayidi (Al2O3) monga chigawo chachikulu.

Mawonekedwe:

Kukana kuvala kwakukulu; Kukana kutentha kwakukulu; Kukana kwa dzimbiri; Kuuma kwakukulu; Mkulu compressive mphamvu; Kukhazikika kwamafuta abwino

Ntchito:

Thandizo la Catalyst ndi tower filler:Mu riyakitala, mipira ya alumina ceramic imagwiritsidwa ntchito ngati chothandizira kuphimba zida zothandizira ndi zodzaza nsanja kuti awonjezere malo ogawa gasi kapena madzi kuti apititse patsogolo magwiridwe antchito ndikuteteza chothandizira ndi mphamvu zochepa. pa

Media Media:Amagwiritsidwa ntchito kwambiri pazida zogayira zabwino monga mphero za mpira ndi mphero zonjenjemera pogaya ores, slurries, zinthu zosavala, ndi ufa monga zokutira ndi utoto. Kukaniza kwake kovala bwino komanso kuzungulira kumatha kupewa zipsera panthawi yopukutidwa komanso kukhudzana kwambiri ndi chinthu chopukutira. pa

Mapulogalamu ena:Amagwiritsidwanso ntchito kwambiri m'mafakitale ambiri monga petrochemicals, zomanga zadothi zaukhondo, mchere wopanda zitsulo, zitsulo, ndi zamagetsi.

pa(2) Alumina akupera mpirandi mtundu wa sing'anga akupera zopangidwa bauxite, wodzigudubuza ufa, mafakitale aluminiyamu ufa, etc., kudzera batching, akupera, kupanga ufa, akamaumba, kuyanika, sintering ndi njira zina. Chigawo chake chachikulu ndi α-Al2O3, chomwe chili ndi zizindikiro za kuuma kwakukulu, kukana kuvala kwambiri ndi kukhazikika kwa mankhwala, ndipo zimagwiritsidwa ntchito kwambiri pogaya ndi kupukuta.

Ntchito:

Makampani a Ceramic ndi Magalasi:amagwiritsidwa ntchito pogaya glaze ndi ufa wa ceramic kuti apangitse kufanana ndi kutha kwa chinthucho. pa

Makampani okutira:amagwiritsidwa ntchito pogaya ndi kumwaza zokutira zokhala ndi madzi ndi mafuta kuti apititse patsogolo madzi ndi kumamatira kwa zokutira. pa

Makampani apakompyuta:amagwiritsidwa ntchito pogaya mwatsatanetsatane mbali zamakina ndi zida zowoneka bwino kuti zitsimikizire kulondola kwambiri komanso mawonekedwe abwino. pa

Zatsopano zamagetsi:amagwiritsidwa ntchito pogaya zida za batri ya lithiamu kulimbikitsa kugawa yunifolomu ndikuwongolera magwiridwe antchito azinthu. Chitetezo cha chilengedwe: chimagwiritsidwa ntchito pochiza madzi otayira komanso kutaya madzi am'madzi kuti achotse zonyansa ndi zoipitsa m'madzi.

Mulingo wa tinthu:0.3-0.4, 0.4-0.6, 0.6-0.8, 0.8-1.0, 1.0-1.2, 1.2-1.4, 1.4-1.6, 1.8-2.0, 2.0-2.2, 2.2-2.4, 2.8-3.3, 3.2-3. 4.5-5.0, 5.0-5.5, 6.0-6.5, 6.5-7.0, 8, 10, 12, 15, 20

Alumina Akupera Mipira

Mipira ya Alumina Ceramic

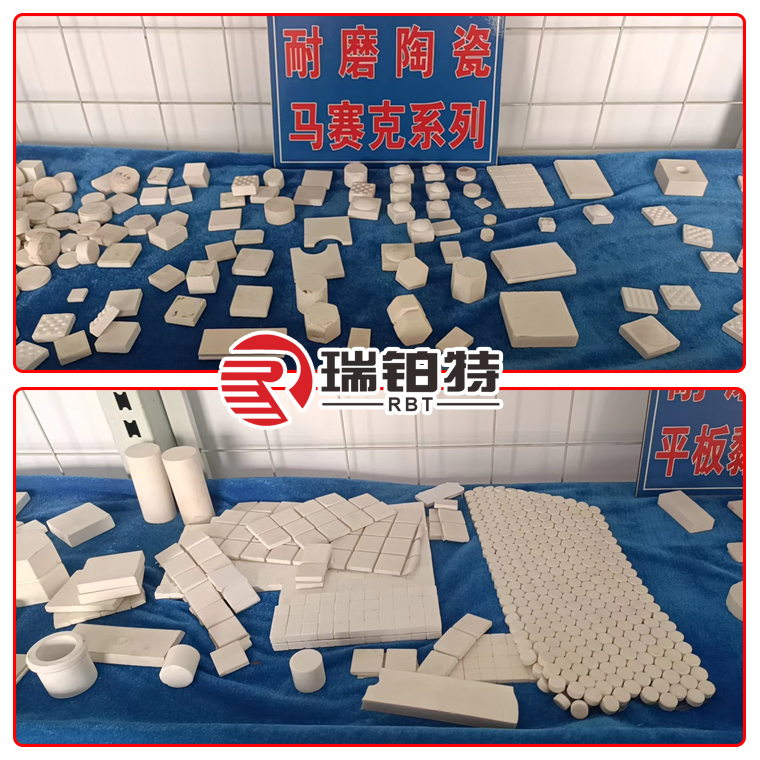

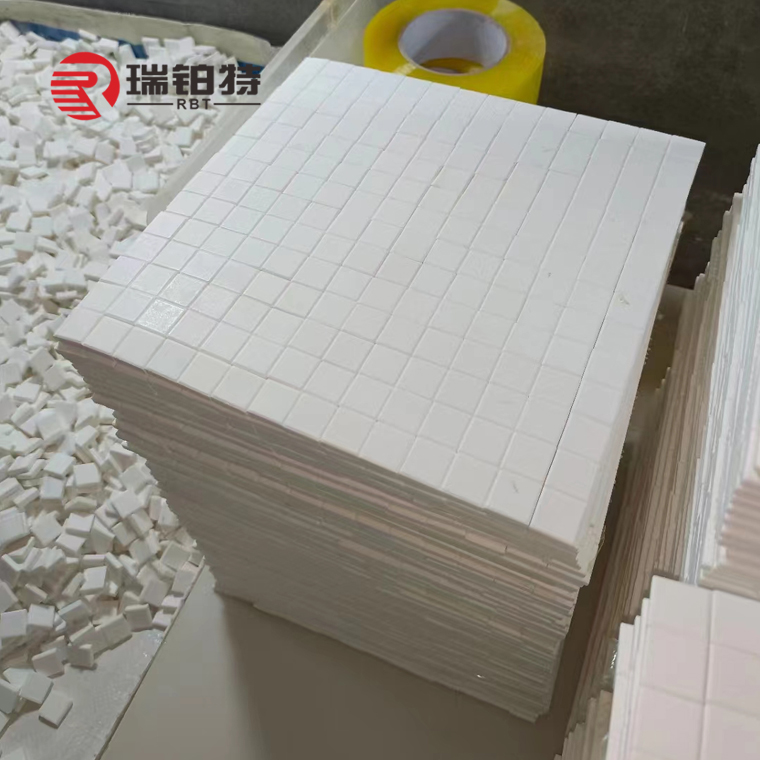

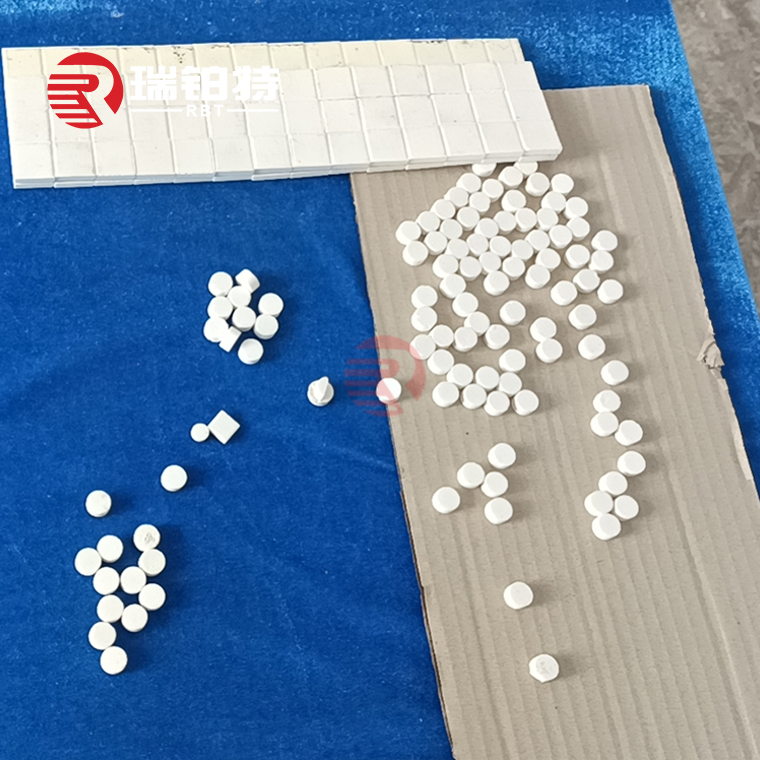

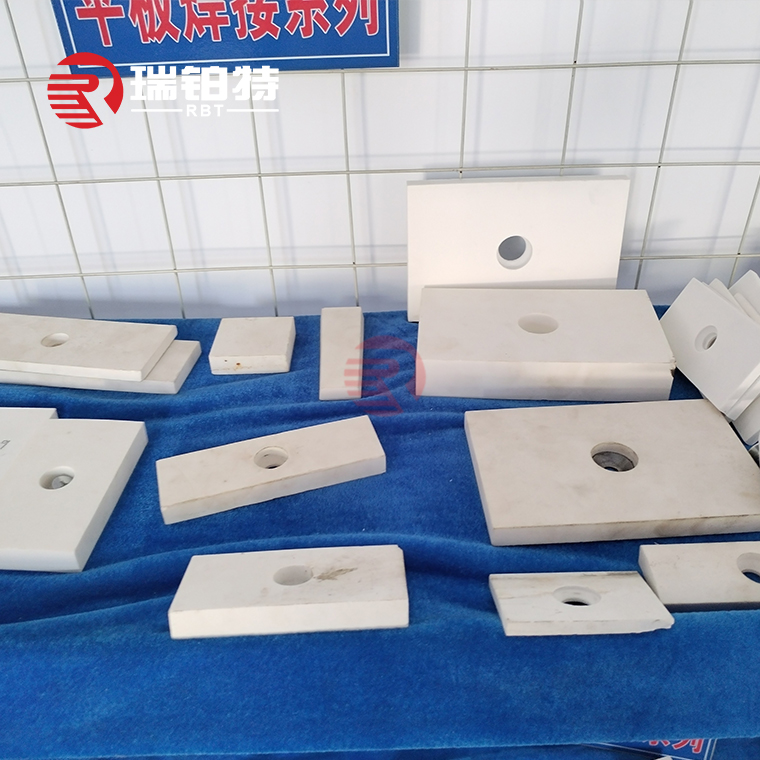

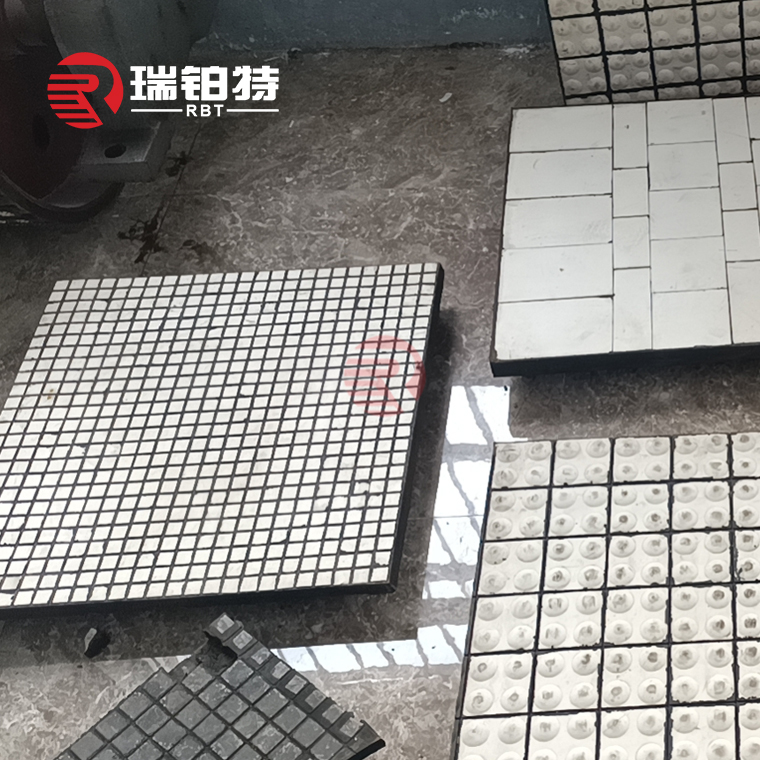

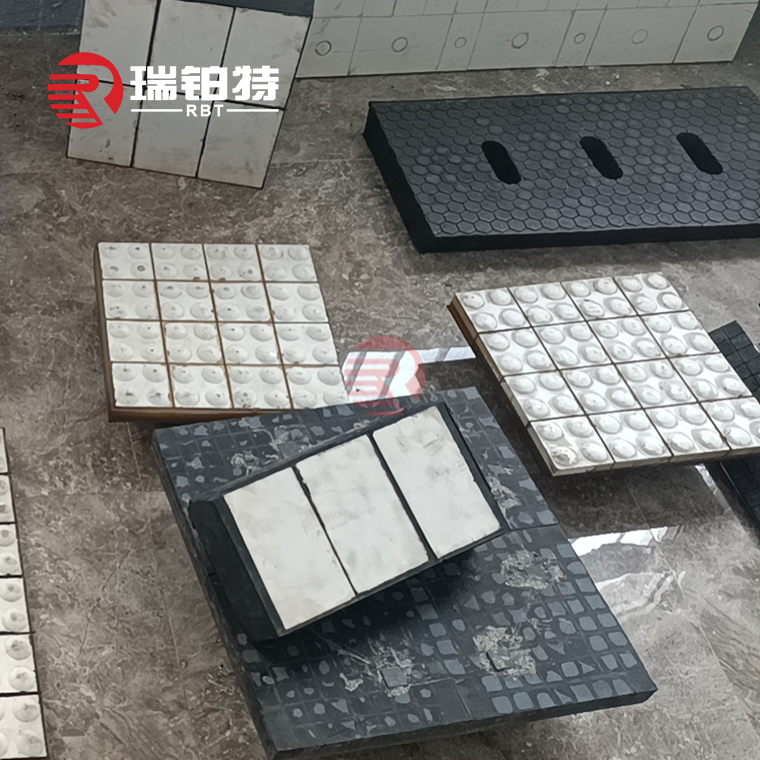

2. 92%, 95% Alumina Wear-resistant Ceramics(zachilendo, zooneka mwapadera, zopangidwa makonda)

(1) Chojambula cha ceramic chosamva kuvala matailosindi zida za ceramic zogwira ntchito kwambiri, makamaka zopangidwa ndi zida zamphamvu kwambiri za ceramic monga alumina ndi silicon nitride. Pamwamba pake amathandizidwa ndi njira zapadera ndipo ali ndi kuuma kwambiri komanso kukana kuvala. Kupanga kwake kumaphatikizapo matekinoloje apamwamba monga kukanikiza kowuma ndi grouting, ndipo mawonekedwe ake ndi osiyanasiyana

kukwaniritsa zosowa zamafakitale osiyanasiyana.

Mawonekedwe:

1. Kuuma kwakukulu:Kulimba kwa Rockwell kwa ma ceramic mosaic osavala kumafika pa HRA80-90, yachiwiri kwa diamondi, ndipo kumakhala kolimba kwambiri komanso kukana kuvala.

2. Kukana kuvala:Kukana kwake kuvala kumakhala kofanana ndi 266 nthawi ya chitsulo cha manganese ndi 171.5 nthawi ya chitsulo chachitsulo cha chromium, kusonyeza kukana kuvala.

3. Kulemera kwake:Kachulukidwe kake ndi 3.6g/cm³, yomwe ndi theka la chitsulo, chomwe chingachepetse kwambiri kuchuluka kwa zida ndikuwongolera magwiridwe antchito a zida.

4. Kumanga kosavuta:Ceramic mosaic yosamva kuvala ndiyosavuta kuyiyika ndikuyisamalira, kuchepetsa zovuta komanso mtengo womanga.

Ntchito:

Makampani a Petrochemical:amagwiritsidwa ntchito ngati zingwe zomangira komanso zosagwira ntchito mumagetsi, mapaipi, matupi amapope ndi zida zina, kukulitsa moyo wa zida ndikuwongolera chitetezo.

Migodi ndi Metallurgy:kuwongolera kwambiri kukana kuvala komanso kupanga bwino pamagawo ovala azipangizo monga mphero mpira, mphero malasha, ndi pulping makina. pa

Makampani opanga magetsi:amagwiritsidwa ntchito m'magawo osamva kuvala amagetsi opangira malasha, magetsi opangira gasi ndi zida zina, monga zoyatsira, mphero zamakala, ndi otolera fumbi, kuwongolera bwino moyo wautumiki komanso kugwiritsa ntchito bwino zida. pa

Kupanga makina:amagwiritsidwa ntchito popanga zida zolondola kwambiri, zosavala kwambiri, monga ma bearing, magiya, ndi njanji zowongolera, kuwongolera kwambiri magwiridwe antchito ndi kudalirika kwa zinthu zamakina.

(2) Njerwa zadothi zadothi zosagwira ntchitoNthawi zambiri amapangidwa ndi zinthu za ceramic ndi matrix. Zida za ceramic nthawi zambiri zimagwiritsa ntchito zoumba zapamwamba za alumina kapena zirconia ceramics, zomwe zimakhala ndi mphamvu zolimba komanso zolimba. Zinthu za matrix nthawi zambiri zimakhala zitsulo kapena zitsulo zina, zomwe zimapereka chithandizo chofunikira komanso cholimba. Mwa kuphatikiza wosanjikiza wa ceramic ndi matrix achitsulo, chinthu chophatikizika chomwe sichimva kuvala komanso cholimba mokwanira chimapangidwa.

Ntchito:

Makina opangira migodi:Tetezani zida zophwanyidwa ndi zowunikira kuti zisawonongeke. pa

Metallurgical industry:Amagwiritsidwa ntchito mu ng'anjo zotentha kwambiri komanso zida zoponyera chifukwa cha kukana kwake kutentha kwambiri komanso kukana dzimbiri. pa

Makampani opanga magetsi:Amagwiritsidwa ntchito poteteza makina operekera ufa wa malasha ndi ng'anjo za boiler. pa

Kupanga simenti:Chepetsani kulumikizana kwachindunji pakati pa malamba otumizira ndi zida ndikukulitsa moyo wa zida. pa

Chemical industry:Amagwiritsidwa ntchito pazida monga mphero za mpira kuti awonjezere kutulutsa ndi kugaya bwino, kuchepetsa kugwiritsa ntchito mphamvu komanso kukonza ndalama.

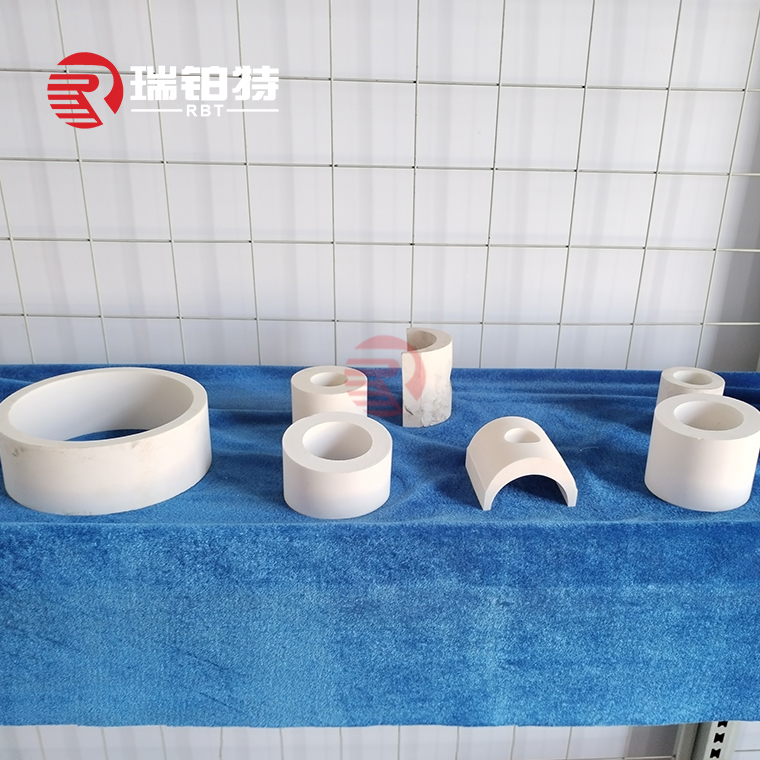

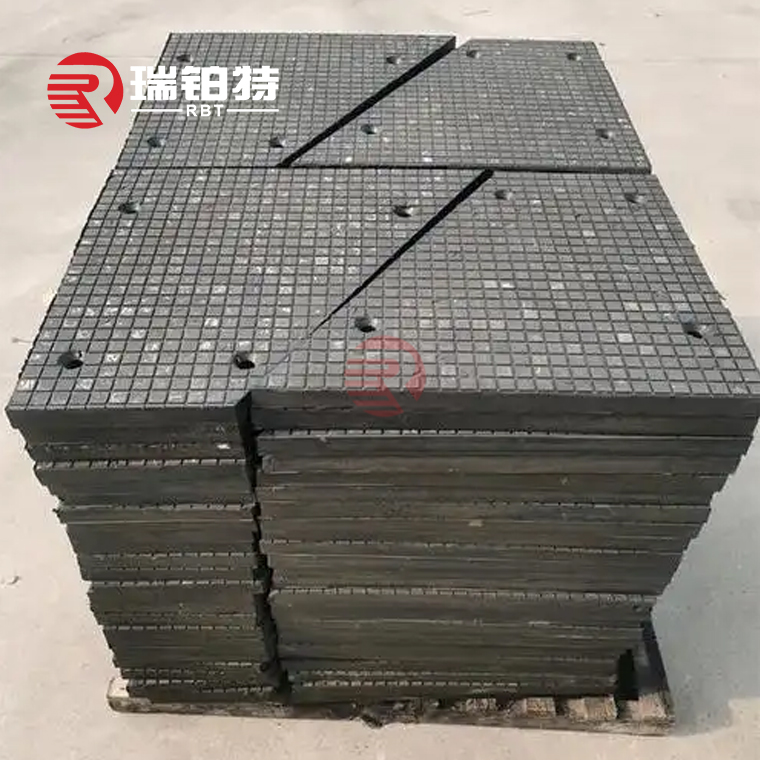

(3) Zovala zadothi zadothi zosavala mbalendi zinthu zokhala ndi aluminiyamu (AL2O3) monga thupi lalikulu, zowonjezeredwa ndi zosakaniza zina, ndipo zimatenthedwa pa kutentha kwakukulu kwa 1700 ° C. Ili ndi kukana kwabwino kwambiri, kukana kwa dzimbiri komanso kukhazikika kwa kutentha kwambiri, ndipo imagwiritsidwa ntchito kwambiri potengera malasha, makina otumizira zinthu, makina opangira ufa, kutulutsa phulusa, kutulutsa phulusa, makina ochotsa fumbi ndi zida zina zamakina zokhala ndi mphamvu zotentha, zitsulo, zitsulo, makina, malasha, migodi, mankhwala, simenti, madoko ndi mabizinesi ena.

Mapulogalamu:

Makampani a Migodi:Pa nthawi ya migodi, zipangizo nthawi zambiri zimakhudzidwa ndi abrasives ndi zotsatira. Kugwiritsa ntchito zingwe za ceramic zosagwira ntchito kumatha kukulitsa moyo wautumiki wa zida ndikuchepetsa mtengo wokonza.

Makampani a Metallurgical:Pazida zopangira zitsulo, zitsulo zosagwira ntchito za ceramic zimatha kukana kukokoloka kwa zitsulo zosungunuka ndi miyala yamtengo wapatali kuti zitsimikizidwe kuti zida zikugwira ntchito mokhazikika.

Makampani a Chemical:Popanga mankhwala, zida nthawi zambiri zimawonetsedwa ndi media zowononga. Kugwiritsa ntchito zingwe za ceramic zosagwira ntchito zimatha kupititsa patsogolo kulimba kwa zida ndikuchepetsa kulephera komwe kumachitika chifukwa cha dzimbiri. pa

Makampani opanga magetsi:Pazida zamagetsi, zomangira za ceramic zosagwira ntchito zimatha kuchepetsa kuvala kwa fumbi ndi tinthu tating'ono tolimba pazida, kuwonetsetsa kuti zidazo zikugwira ntchito kwanthawi yayitali.

(4) Zida Zapadera Zosavala za Ceramic

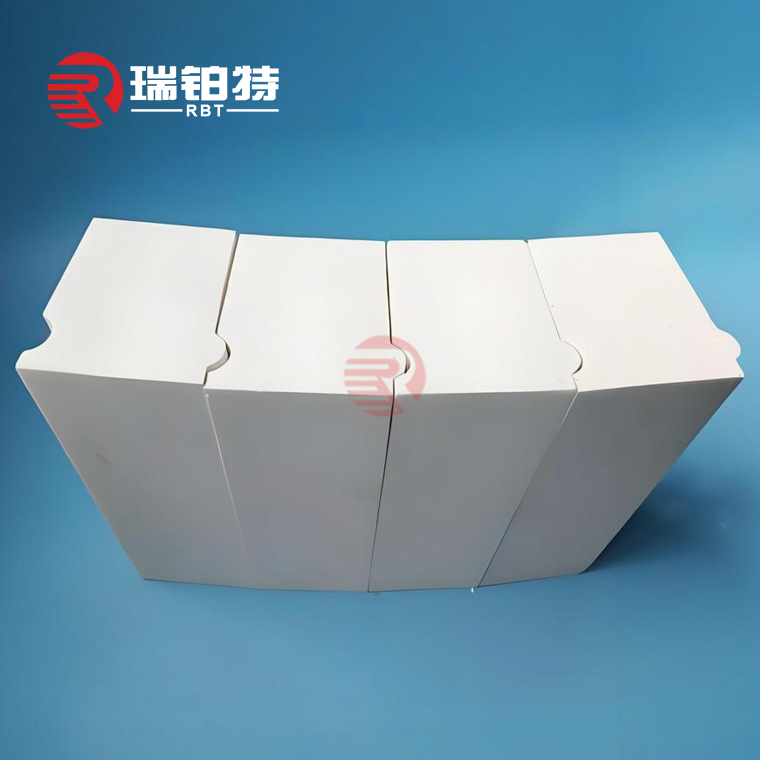

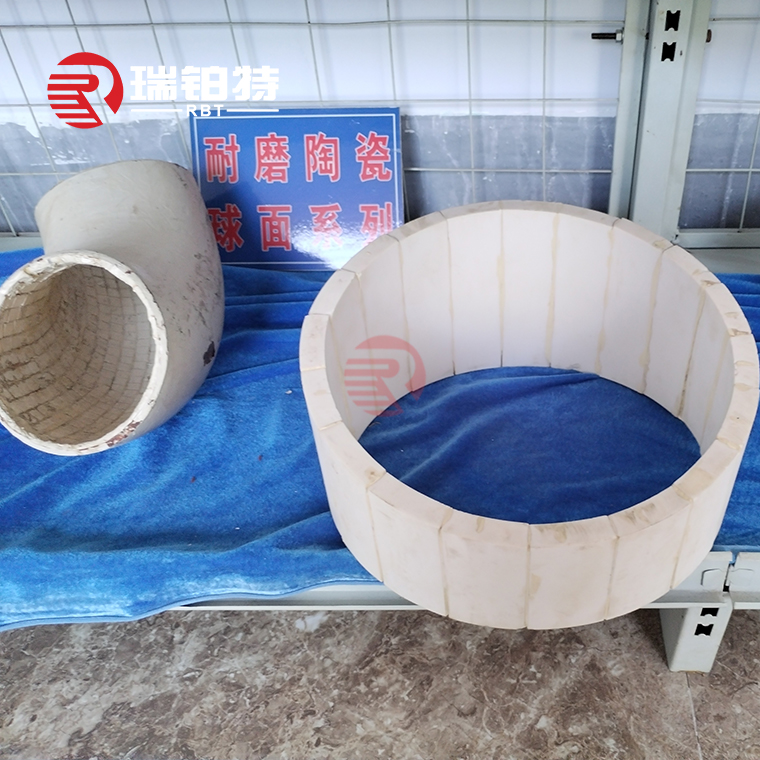

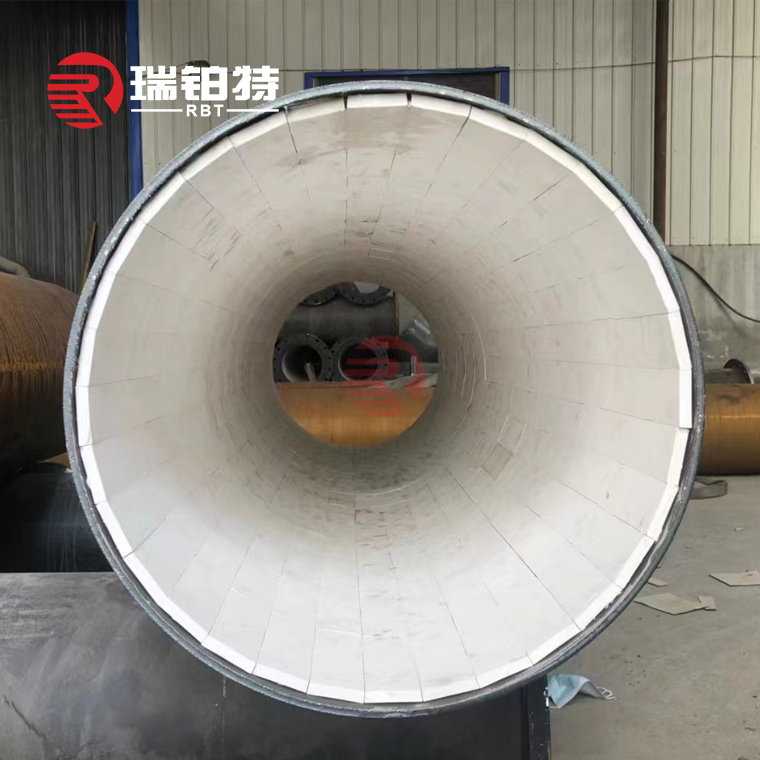

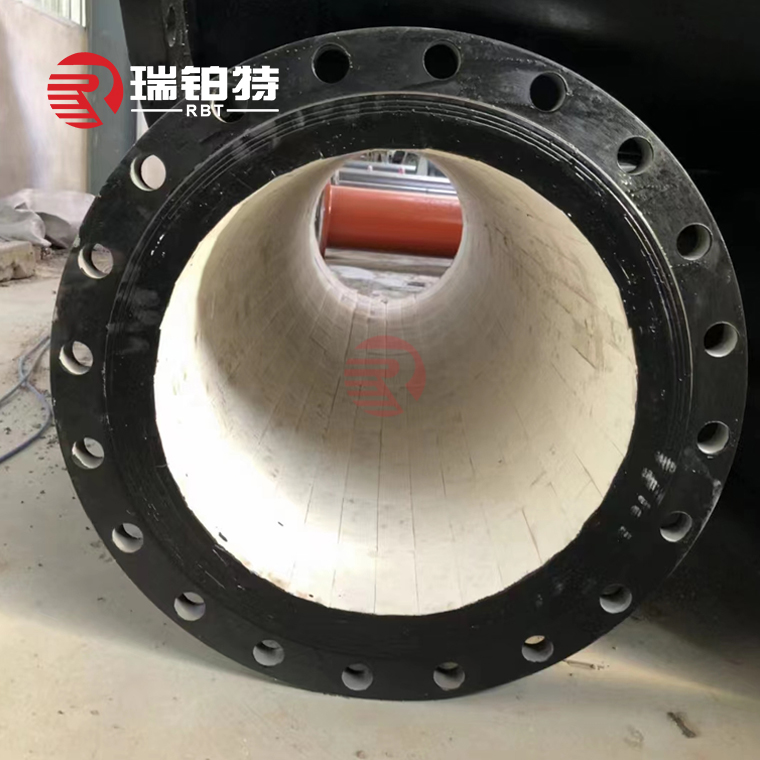

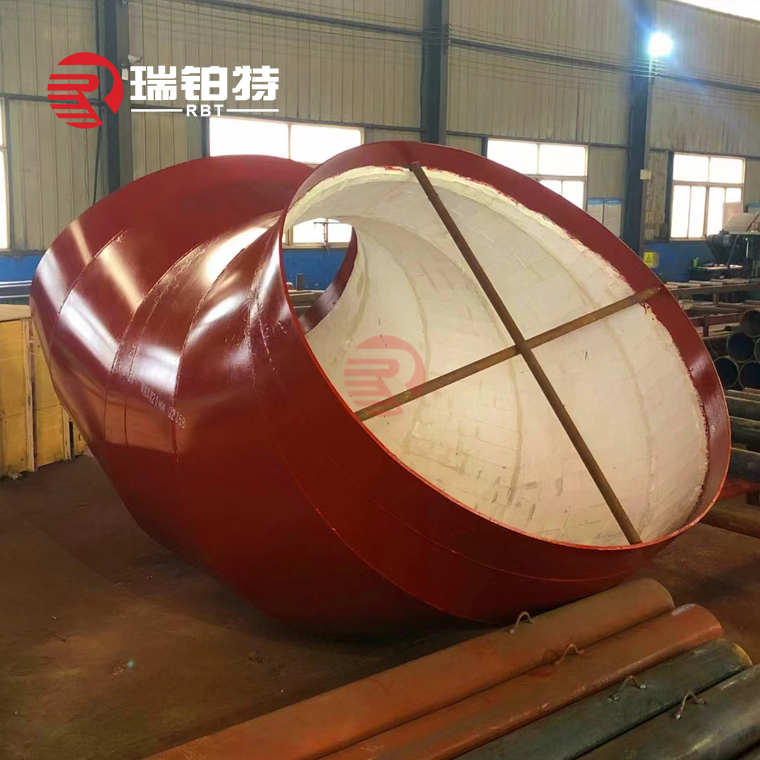

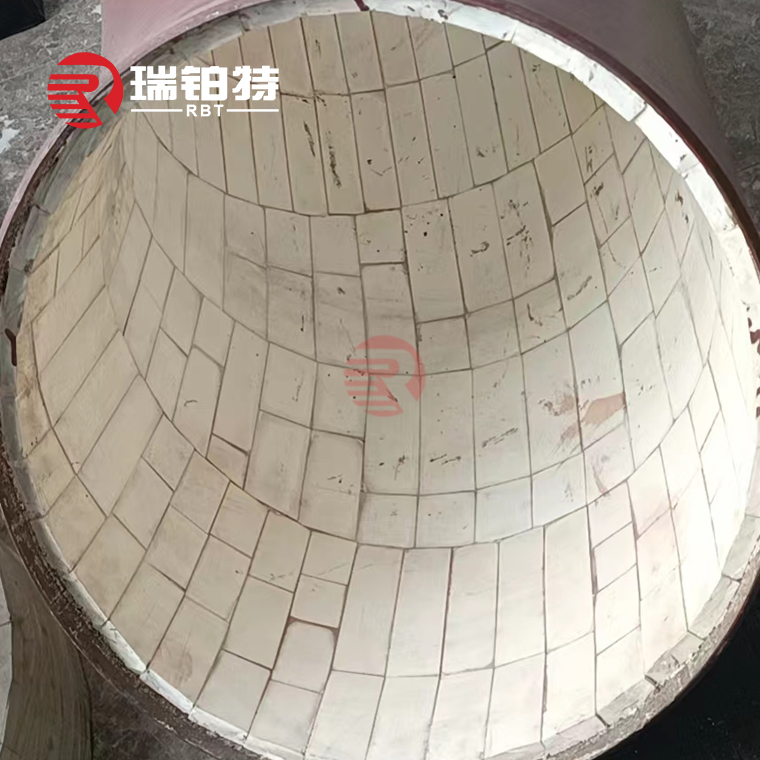

3. Chitoliro chosamva kuvala cha ceramic kompositi, dzina lonse ceramic alimbane gulu zitsulo chitoliro, ndi chitoliro chopangidwa ntchito chatekinoloje kupanga ndondomeko - kudzikonda kufalitsa mkulu-kutentha zowalamulira kaphatikizidwe njira.

Mawonekedwe:

Kukana kuvala kwakukulu:Kuuma kwa Mohs kwa corundum ceramic lining kumatha kufika 9.0, komwe kumakhala kolimba kwambiri ndipo kuli koyenera kutumizira mauthenga a abrasive. pa

Kulimbana ndi Corrosion:Zida za Ceramic zimalimbana bwino ndi zinthu zowononga monga ma acid, alkalis, ndi mchere. pa

Kukhazikika kwa kutentha kwakukulu:Chosanjikiza cha ceramic chimakhala ndi kukhazikika kwamafuta ambiri komanso kukana kwa okosijeni, ndipo ndi koyenera kumadera otentha kwambiri. pa

Wopepuka komanso wamphamvu kwambiri:Pakati pa mapaipi amtundu womwewo komanso kutalika kwa unit, chitoliro chosamva za ceramic composite chitoliro ndi chopepuka, koma chimakhala cholimba kukana kuvala ndi kukokoloka kwamadzimadzi.

Ntchito:

Mapaipi osamva kuvala a ceramic composite mapaipi amagwiritsidwa ntchito kwambiri mu mphamvu, zitsulo, migodi, malasha, mankhwala ndi mafakitale ena potumiza zinthu zowononga granular ndi zinthu zowononga monga mchenga, miyala, ufa wa malasha, phulusa, madzi a aluminiyamu, ndi zina zambiri.

Njira yopanga

Centrifugal kuponyera gulu ceramic chitoliro:Amapangidwa pogwiritsa ntchito "teknoloji yodzipangira yokha kutentha kwapamwamba-kuthamanga kwambiri kwa centrifugal". Njirayi ndi yosavuta ndipo mtengo wake ndi wotsika. Ndizoyenera kunyamula ufa wautali. pa

Chitoliro cha ceramic chosamva chigamba:Chipepala cha alumina ceramic chimayikidwa pakhoma lamkati la chitoliro kudzera pa zomatira zolimba zosagwira kutentha kwambiri. Njira yopanga ndi yosavuta komanso mtengo wake ndi wotsika. pa

Chitoliro chodzifalitsa chokha:Mwa kusakaniza ufa wa ceramic ndi ufa wachitsulo, umayikidwa pakhoma lamkati la chitoliro pogwiritsa ntchito kaphatikizidwe kapamwamba ka kutentha ndi njira za centrifugal. Chitoliro chophatikizika cha ceramic : Ufa wa ceramic umalowetsedwa mu chitoliro cha ceramic molingana ndi nkhungu ndikuphatikizidwa ndi chitoliro chachitsulo.

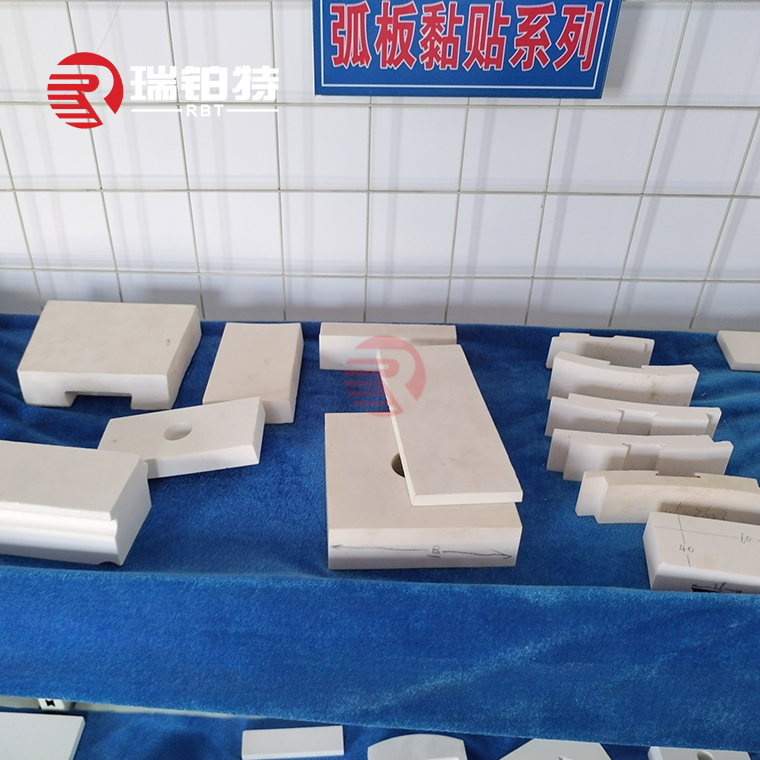

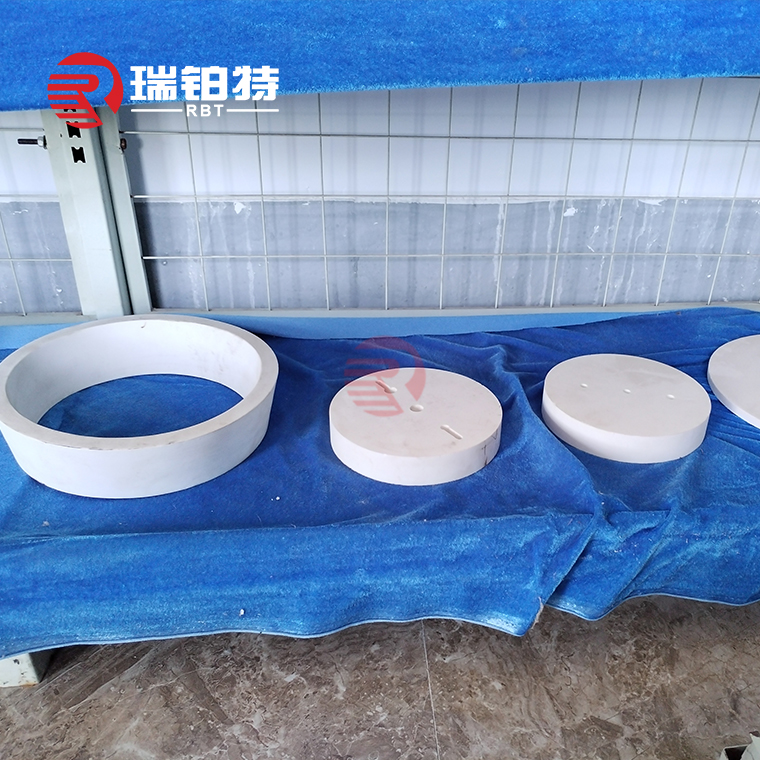

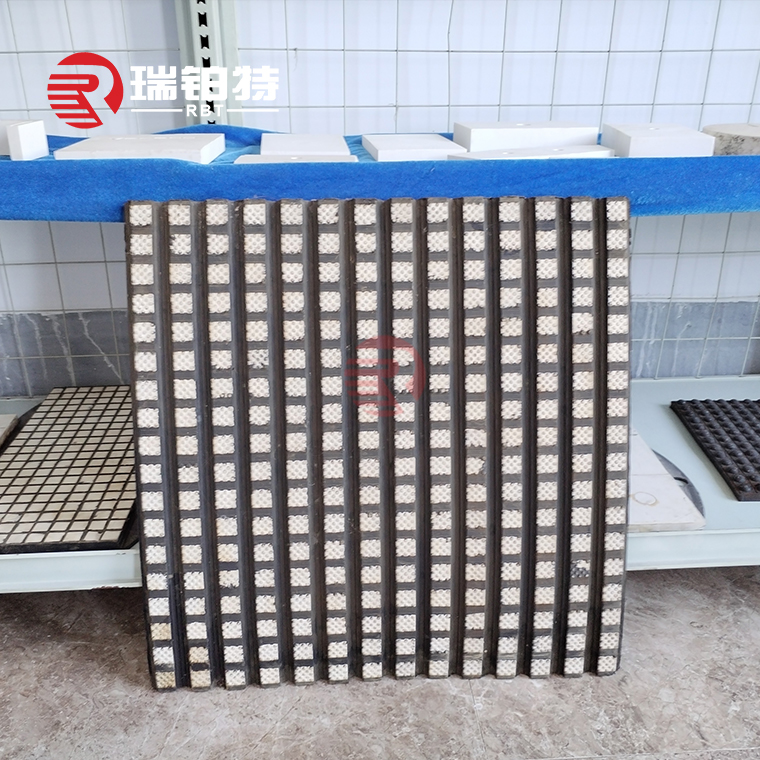

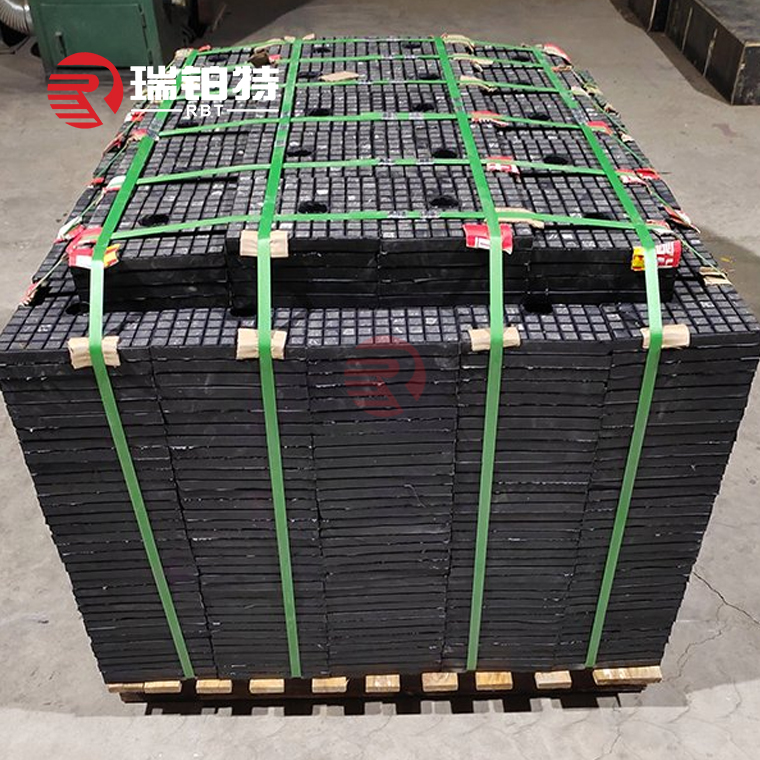

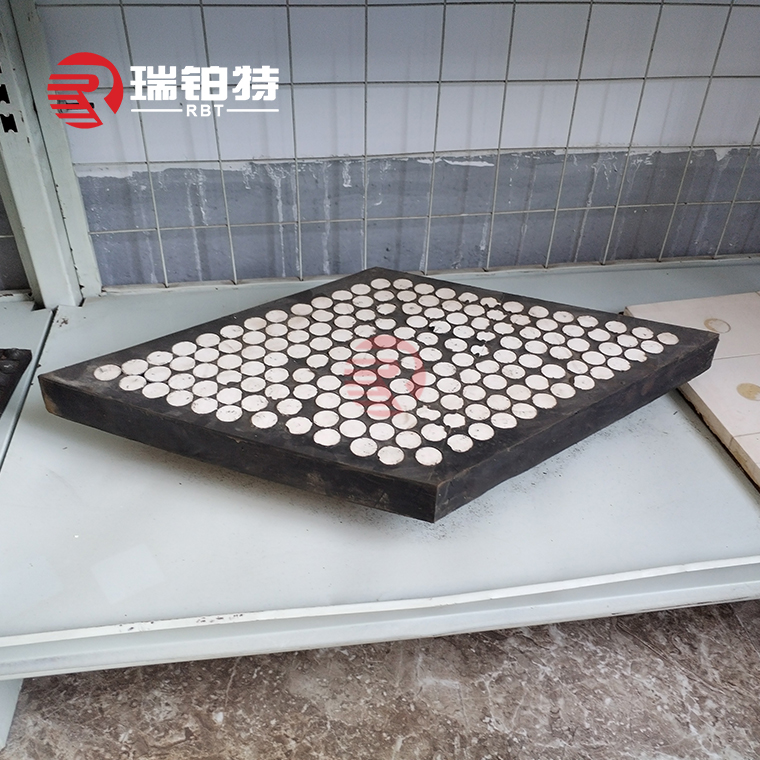

4. Awiri-m'modzi ndi atatu-mu-modzi ceramicmbale zophatikizandi zinthu zophatikizika zomwe zimaphatikiza zida za ceramic ndi mphira, zokhala ndi kukana kovala bwino, kukana dzimbiri komanso kukana kwamphamvu.

Njira yopanga

Mitundu iwiri-imodzi ya mphira wa ceramicmbale:Kupyolera mu ukadaulo wa raba vulcanization, zolimba za alumina zolimba kwambiri zimatenthedwa ndikuphatikizidwa mu rabara yapadera kuti apange gulu la mphira wa ceramic. Kaphatikizidwe kameneka kamakhala ndi magwiridwe antchito abwino ndipo imatha kuletsa kukhudzidwa kwa miyala ndi zinthu zina zomwe zikugwa kuchokera pamalo okwera. pa

Mitundu itatu-imodzi-imodzi yosamva kuvala ya ceramic kompositimbale:Pamaziko a awiri-m'modzi, mbale yachitsulo imawonjezeredwa. Kupyolera mu luso la mphira vulcanization, mphira wa ceramic composite amatenthedwa pamodzi ndi mbale yachitsulo yokhala ndi ma bolt osunthika kuti apange chinsalu chophatikizika chokhala ndi katatu-mumodzi. Kapangidwe kameneka kamapangitsa kuti pakhale mgwirizano wapakati pakati pa zitsulo za ceramic, mphira ndi zitsulo, pomwe zimapereka zowonjezera zowonjezera.

Makhalidwe amachitidwe

Kukana kuvala:Chosanjikiza cha ceramic chimakhala ndi kuuma kwambiri, komwe kumatha kukana kuvala ndikukulitsa moyo wautumiki wa zida.

paImpact resistance:Wosanjikiza mphira amakhala ndi kukhazikika bwino komanso kukana kwamphamvu, amatha kuyamwa komanso kugwedezeka komwe kumapangidwa panthawi yogwiritsira ntchito zida, ndikuteteza gawo la ceramic kuti lisawonongeke. pa

Kulimbana ndi Corrosion:Zonse za ceramic ndi mphira zimakhala ndi kukana kwa dzimbiri ndipo zimatha kugwira ntchito mokhazikika kwa nthawi yayitali m'malo ovuta. pa

Opepuka:Chimbale cholowera mumitundu itatu-mu-chimodzi ndichopepuka kuposa 60% kuposa mbale yachitsulo yosamva kuvala, ndipo ndiyosavuta kuyiyika ndikusintha.

Ntchito:

Migodi:Amagwiritsidwa ntchito pazida zosamva kuvala monga mphero za mpira, mphero zamakala, zokwezera ndowa,scraper conveyors, etc. kuti apititse patsogolo magwiridwe antchito komanso kukhazikika kwa zida. pa

Metallurgy:Pazida zosiyanasiyana zamafakitale opangira zitsulo, mbale zosagwirizana ndi ceramic zosakanikirana zimatha kukana kuvala kwa kutentha kwambiri, kuthamanga kwambiri ndi zida zowononga. pa

Magetsi:Mu kayendedwe ka malasha, zida zochotsera fumbi ndi mbali zina zamakampani amagetsi, zimachepetsa kuvala kwa zida ndikuchepetsa mtengo wokonza. pa

Chemical industry:Mu reactors, akasinja osungira ndi zipangizo zina mu makampani mankhwala, kukana kukokoloka kwa zosiyanasiyana mankhwala TV ndi kuwonjezera moyo utumiki zida.

Mndandanda wazinthu

| Kanthu | Al2O3 >92% | >95% | >99% | >99.5% | >99.7% |

| Mtundu | Choyera | Choyera | Choyera | Mtundu wa Kirimu | Mtundu wa Kirimu |

| Kachulukidwe Kaganizidwe(g/cm3) | 3.45 | 3.50 | 3.75 | 3.90 | 3.92 |

| Bend Strength (Mpa) | 340 | 300 | 330 | 390 | 390 |

| Compressive Strength(Mpa) | 3600 | 3400 | 2800 | 3900 pa | 3900 pa |

| Elastic Modulus (Gpa) | 350 | 350 | 370 | 390 | 390 |

| Kukaniza Kwamphamvu (Mpam1/2) | 4.2 | 4 | 4.4 | 5.2 | 5.5 |

| Weibull Coefficient(m) | 11 | 10 | 10 | 12 | 12 |

| Vickers Kuuma (HV 0.5) | 1700 | 1800 | 1800 | 2000 | 2000 |

| Thermal Expansion Coefficient | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

| Thermal Conductivity (W/mk) | 18 | 24 | 25 | 28 | 30 |

| Thermal Shock Stability | 220 | 250 | 250 | 280 | 280 |

| Kutentha Kwambiri Kwambiri ℃ | 1500 | 1600 | 1600 | 1700 | 1700 |

| 20 ℃ Kukaniza kwa Voliyumu | >10^14 | >10^14 | >10^14 | >10^15 | >10^15 |

| Mphamvu ya Dielectric(kv/mm) | 20 | 20 | 20 | 30 | 30 |

| Dielectric Constant | 10 | 10 | 10 | 10 | 10 |

Chiwonetsero cha Fakitale

Mbiri Yakampani

Malingaliro a kampani Shandong Robert New Material Co., Ltd.ili mu Zibo City, Province Shandong, China, amene ndi refractory zinthu kupanga m'munsi. Ndife makampani amakono omwe amaphatikiza kafukufuku ndi chitukuko, kupanga, kugulitsa, kapangidwe ka ng'anjo ndi zomangamanga, ukadaulo, ndi zida zotumizira kunja. Tili ndi zida zonse, ukadaulo wapamwamba, mphamvu zolimba zaukadaulo, mtundu wabwino kwambiri wazinthu, komanso mbiri yabwino. Fakitale yathu imakhala ndi maekala opitilira 200 ndipo zotulutsa zowoneka bwino zowoneka bwino zimakhala pafupifupi matani 30000 ndipo zida zosapanga dzimbiri ndi matani 12000.

Zogulitsa zathu zazikulu za zida za refractory ndi:zinthu zamchere refractory; zotayidwa silicon refractory zipangizo; zinthu zosaoneka zokanira; kutchinjiriza matenthedwe refractory zipangizo; zida zapadera zokanira; zinchito refractory zipangizo mosalekeza kuponya kachitidwe.

Mafunso Ofunsidwa Kawirikawiri

Mukufuna thandizo? Onetsetsani kuti mwayendera mabwalo athu othandizira kuti mupeze mayankho a mafunso anu!

Ndife opanga zenizeni, fakitale yathu ndi yapadera popanga zida zokanira kwa zaka zopitilira 30. Timalonjeza kupereka mtengo wabwino kwambiri, ntchito yabwino kwambiri yogulitsiratu komanso yogulitsa pambuyo pake.

Panjira iliyonse yopanga, RBT ili ndi dongosolo lathunthu la QC la kapangidwe kake ndi zinthu zakuthupi. Ndipo tidzayesa katunduyo, ndipo chiphaso chabwino chidzatumizidwa ndi katunduyo. Ngati muli ndi zofunikira zapadera, tidzayesetsa kuti tikwaniritse.

Malingana ndi kuchuluka kwake, nthawi yathu yoperekera ndi yosiyana. Koma tikulonjeza kutumiza mwamsanga ndi khalidwe lotsimikizika.

Inde, timapereka zitsanzo zaulere.

Inde, ndithudi, ndinu olandiridwa kukaona RBT kampani ndi katundu wathu.

Palibe malire, titha kukupatsani malingaliro ndi yankho labwino kwambiri malinga ndi momwe mulili.

Takhala tikupanga zida zokanira kwazaka zopitilira 30, tili ndi chithandizo champhamvu chaukadaulo komanso chidziwitso cholemera, titha kuthandiza makasitomala kupanga ma kilns osiyanasiyana ndikupereka ntchito imodzi.